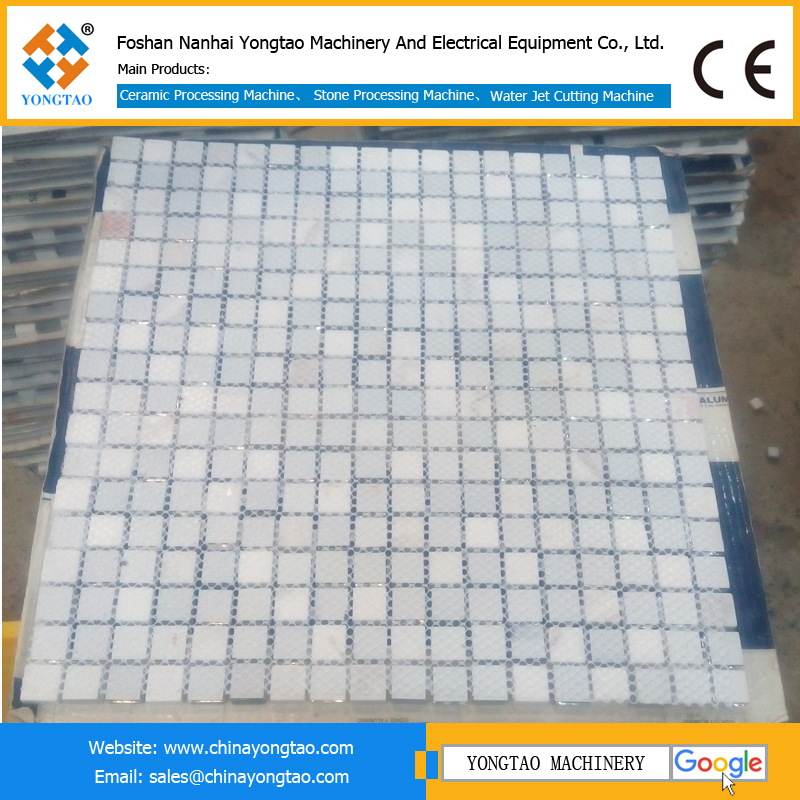

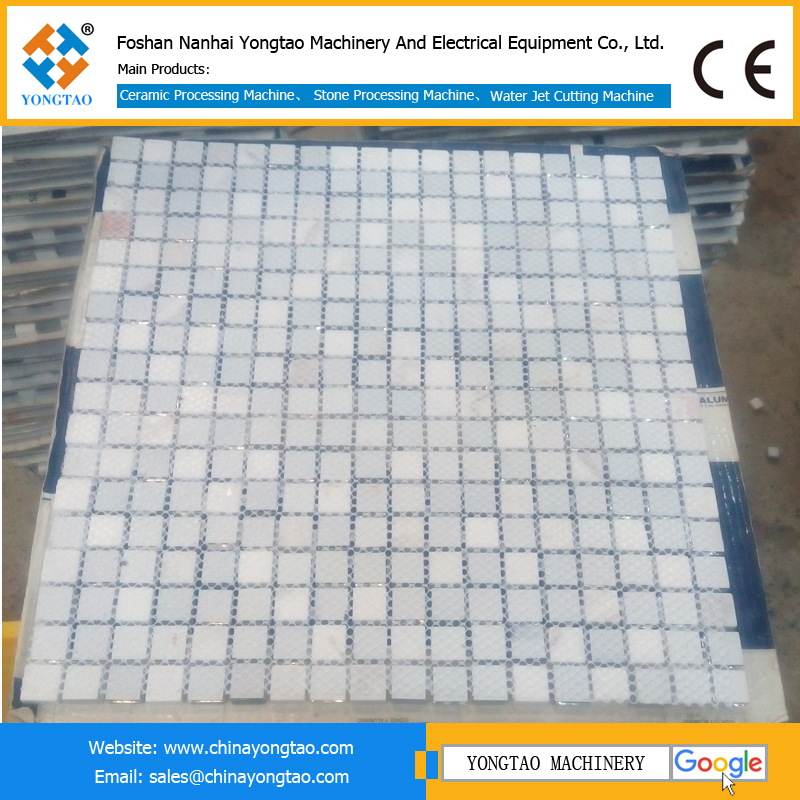

The single spindle mosaic cutter machine is a specialized piece of mosaic machinery designed for cutting floor tiles, stone materials, and the required strip and square tiles. This machine can process bricks with a width ranging from 25mm to 600mm (optional up to 800mm) in a single operation and is equipped with a custom pressure plate for precise cutting of 10x10mm mosaics.

The single spindle mosaic cutter machine is a specialized piece of mosaic machinery designed for cutting floor tiles, stone materials, and the required strip and square tiles. This machine can process bricks with a width ranging from 25mm to 600mm (optional up to 800mm) in a single operation and is equipped with a custom pressure plate for precise cutting of 10x10mm mosaics. Due to its reasonable design and high machining accuracy, the single-spindle multi-blade mosaic cutting machine demonstrates outstanding advantages in cutting efficiency, precision, and production capacity, making it widely used in various construction material processing industries.

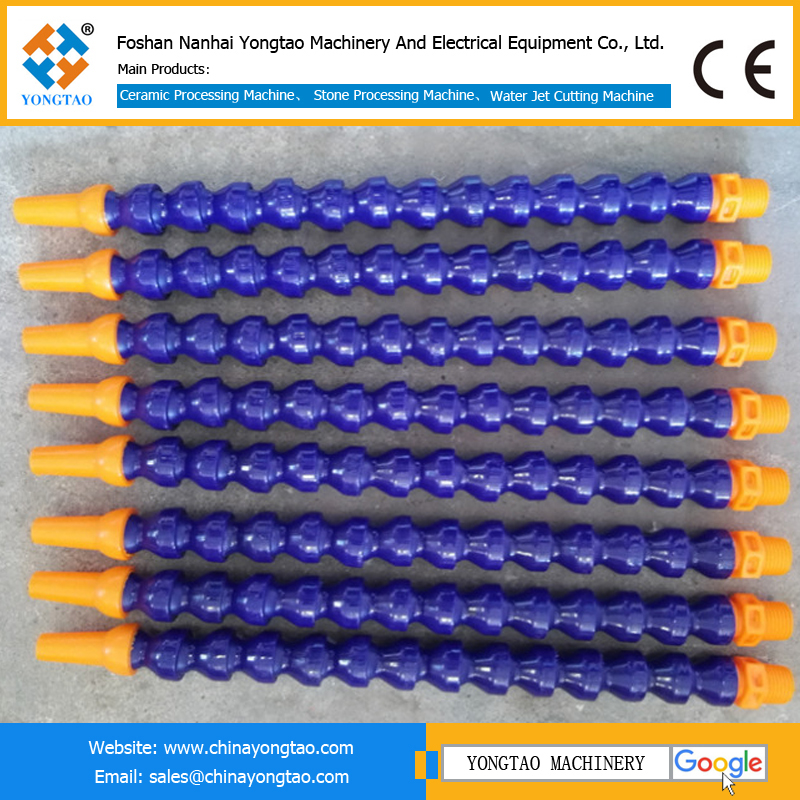

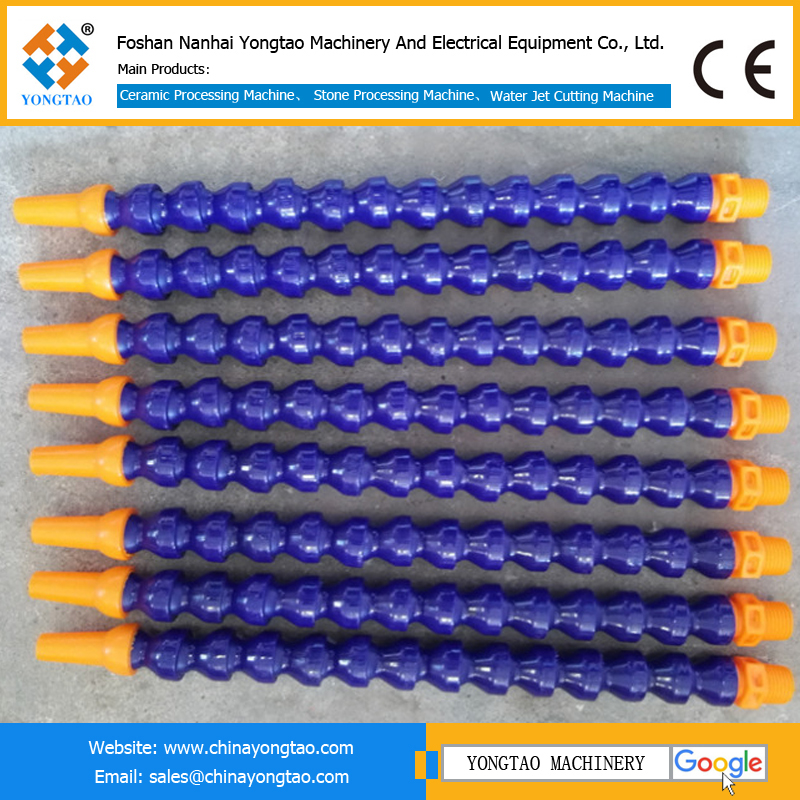

The 800mm mosaic cutter machine boasts several innovative design features that enhance its longevity and cutting accuracy. The spindle box bearing seat is equipped with a water-cooling device, preventing overheating and high temperatures during extended use, effectively prolonging the life of the bearings. Additionally, the machine employs a V-belt guide design to ensure the precision of belt transmission. The combination of a dovetail groove lift and a double-support cantilever structure provides increased stability during cutting, reducing vibration and ensuring consistent processing results.

This machine excels in the ceramic and stone mosaic processing industry, particularly for multi-blade strip and grain cutting of thin stone materials. The equipment can accurately cut mosaic blocks as small as 10x10mm and can process a variety of complex shapes, such as diamond, hexagon, and octagon (when used with mosaic templates). The machine not only offers stable mechanical performance but also significantly improves processing efficiency, ensuring high-quality output, making it an ideal mosaic equipment choice for stone processing enterprises.

The Yongtao 800mm single spindle mosaic cutter equipment is the company's latest high-precision mosaic cutting device, particularly suited for thefine cutting of tiles and stone materials. This machine can process materials up to 800mm in width in a single operation and is equipped with an automatic pressure plate for precise processing of 10x10mm mosaics. Additionally, the Yongtao 800mm single-axis cutting machine's water-cooling device for the bearing seat, precise belt guide system, and double-support cantilever structure design ensure stability and accuracy during cutting. This equipment is also suitable for cutting baseboards, traditional roofing tiles, blue bricks, and other construction materials, providing customers with a more comprehensive cutting solution.

Model and Technical Parameters:

Model | Head of Principal Axis | Width of Conveyor | Dia of Disc | Motor power of Principal Axis |

YJ-1/600 | 1 | 620mm | Φ150/Φ250 | 15KW |

YJ-1/800 | 1 | 820mm | Φ150/Φ250 | 15KW |

Model | Motor power of Conveyor | Speed of Conveyor | Motor power of lifter | Cutting Width |

YJ-1/600 | 0.75KW | 0.8-4.0m/min | 0.75KW | 20-600mm |

YJ-1/800 | 0.75KW | 0.8-4.0m/min | 0.75KW | 20-800mm |

Model | Max Cutting Thickness | Total Capacity | Machine Size | Weight |

YJ-1/600 | 20mm | 16.5KW | 2110*1580*1630 | 1400KG |

YJ-1/800 | 20mm | 16.5KW | 2110*1780*1630 | 1500KG |

The single spindle mosaic cutter machine is a specialized piece of mosaic machinery designed for cutting floor tiles, stone materials, and the required strip and square tiles. This machine can process bricks with a width ranging from 25mm to 600mm (optional up to 800mm) in a single operation and is equipped with a custom pressure plate for precise cutting of 10x10mm mosaics. Due to its reasonable design and high machining accuracy, the single-spindle multi-blade mosaic cutting machine demonstrates outstanding advantages in cutting efficiency, precision, and production capacity, making it widely used in various construction material processing industries.

The 800mm mosaic cutter machine boasts several innovative design features that enhance its longevity and cutting accuracy. The spindle box bearing seat is equipped with a water-cooling device, preventing overheating and high temperatures during extended use, effectively prolonging the life of the bearings. Additionally, the machine employs a V-belt guide design to ensure the precision of belt transmission. The combination of a dovetail groove lift and a double-support cantilever structure provides increased stability during cutting, reducing vibration and ensuring consistent processing results.

This machine excels in the ceramic and stone mosaic processing industry, particularly for multi-blade strip and grain cutting of thin stone materials. The equipment can accurately cut mosaic blocks as small as 10x10mm and can process a variety of complex shapes, such as diamond, hexagon, and octagon (when used with mosaic templates). The machine not only offers stable mechanical performance but also significantly improves processing efficiency, ensuring high-quality output, making it an ideal mosaic equipment choice for stone processing enterprises.

The Yongtao 800mm single spindle mosaic cutter equipment is the company's latest high-precision mosaic cutting device, particularly suited for thefine cutting of tiles and stone materials. This machine can process materials up to 800mm in width in a single operation and is equipped with an automatic pressure plate for precise processing of 10x10mm mosaics. Additionally, the Yongtao 800mm single-axis cutting machine's water-cooling device for the bearing seat, precise belt guide system, and double-support cantilever structure design ensure stability and accuracy during cutting. This equipment is also suitable for cutting baseboards, traditional roofing tiles, blue bricks, and other construction materials, providing customers with a more comprehensive cutting solution.

Model and Technical Parameters:

Model | Head of Principal Axis | Width of Conveyor | Dia of Disc | Motor power of Principal Axis |

YJ-1/600 | 1 | 620mm | Φ150/Φ250 | 15KW |

YJ-1/800 | 1 | 820mm | Φ150/Φ250 | 15KW |

Model | Motor power of Conveyor | Speed of Conveyor | Motor power of lifter | Cutting Width |

YJ-1/600 | 0.75KW | 0.8-4.0m/min | 0.75KW | 20-600mm |

YJ-1/800 | 0.75KW | 0.8-4.0m/min | 0.75KW | 20-800mm |

Model | Max Cutting Thickness | Total Capacity | Machine Size | Weight |

YJ-1/600 | 20mm | 16.5KW | 2110*1580*1630 | 1400KG |

YJ-1/800 | 20mm | 16.5KW | 2110*1780*1630 | 1500KG |