The Stone Straight Edge Chamfering Machine is the latest high-performance stone processing machinery developed by Yongtao Machinery, specifically designed for processing hard materials such as marble, granite, and engineered stone. This equipment combines straight edge polishing and 45-degree chamfer polishing into one, allowing for efficient rough grinding and fine polishing in a single process. This significantly enhances production efficiency, making it the top choice for stone processing companies seeking excellent economic benefits.

The Stone Straight Edge Chamfering Machine is the latest high-performance stone processing machinery developed by Yongtao Machinery, specifically designed for processing hard materials such as marble, granite, and engineered stone. This equipment combines straight edge polishing and 45-degree chamfer polishing into one, allowing for efficient rough grinding and fine polishing in a single process. This significantly enhances production efficiency, making it the top choice for stone processing companies seeking excellent economic benefits.

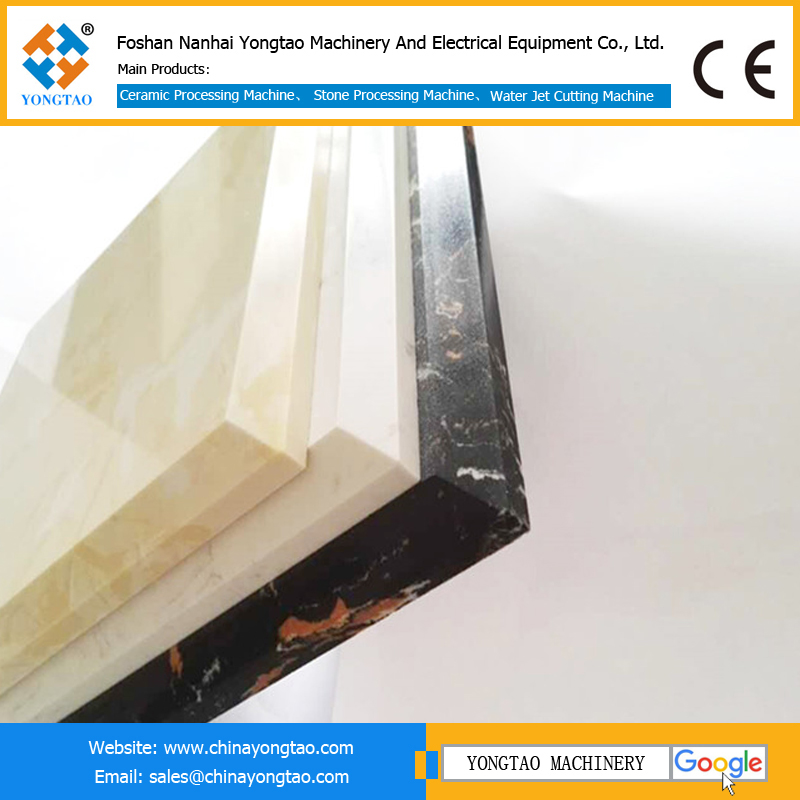

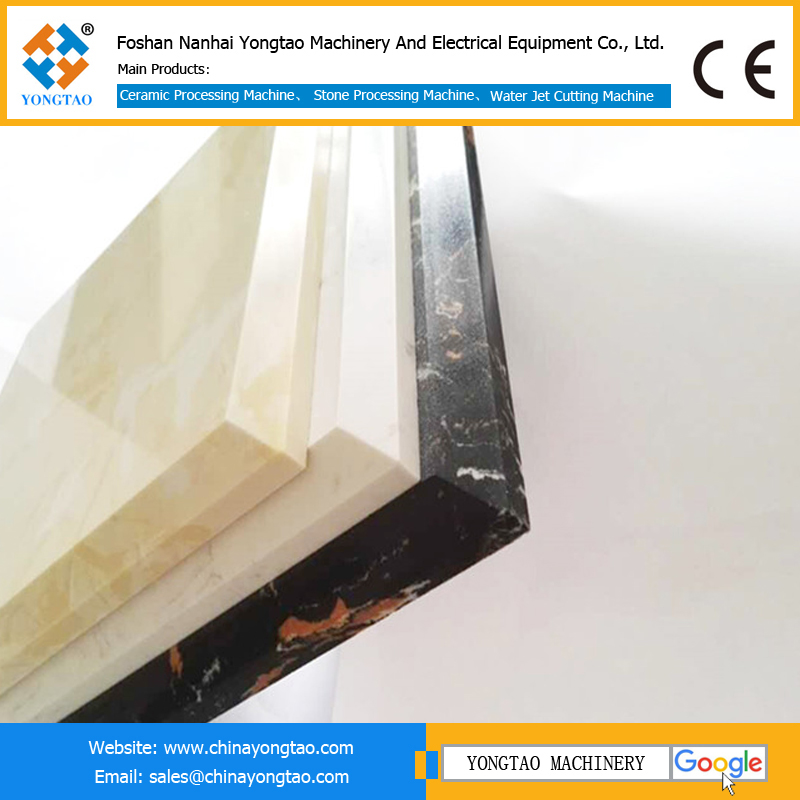

The Yongtao Stone Straight Edge Chamfering Polishing Machine is suitable for processing various stones such as marble, granite, and engineered stone. The equipment supports material processing widths ranging from a minimum of 80mm to a maximum of 800mm, catering to a wide range of processing dimensions, demonstrating strong adaptability.

The machine adopts an advanced design concept, completing the processes of straight edge rough grinding, polishing, and 45-degree chamfer rough grinding, and polishing in one go. This significantly reduces processing time, offering fast processing speeds and excellent results, thereby markedly improving production line efficiency.

The equipment processes materials laid flat, with materials entering from the right side of the machine and exiting from the left after processing. The processing width is adjusted using an electric baffle, and the stainless steel water shield effectively prevents splashing, enhancing the cleanliness of the operating environment.

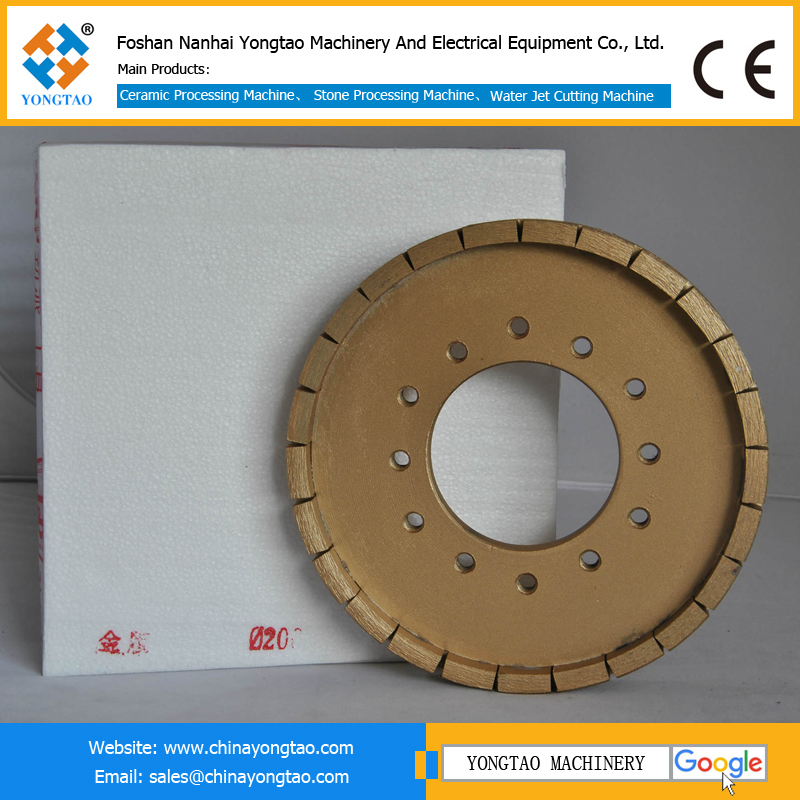

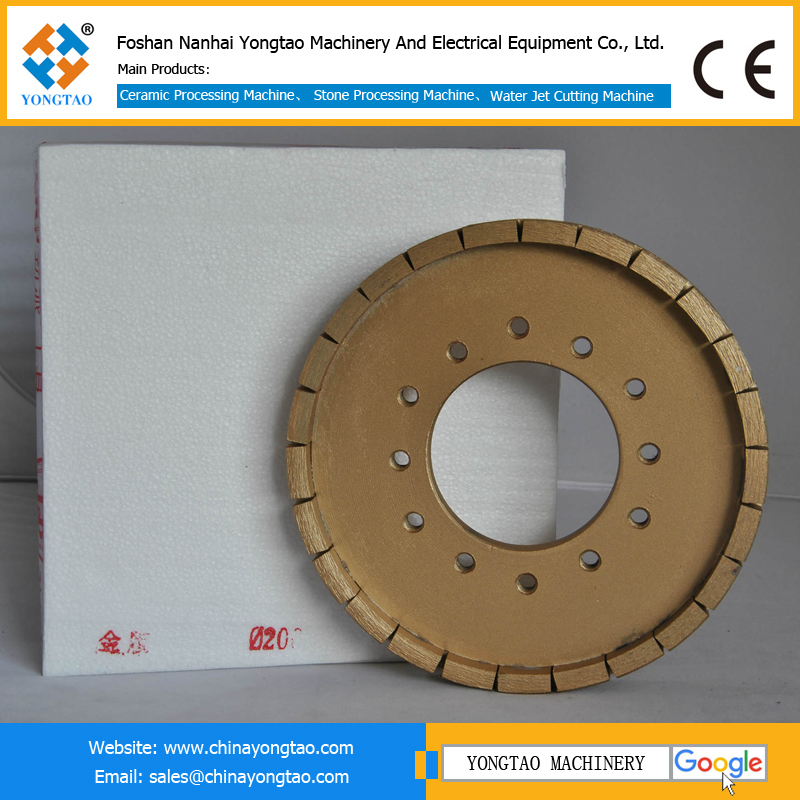

The Yongtao Granite Straight Edge Chamfering Machine is equipped with 1 straight edge rough grinding head and 6 straight edge polishing heads, along with 2 chamfer rough grinding heads and 6 chamfer polishing heads. Each grinding head is equipped with a water outlet to ensure sufficient water flow during processing, preventing the material from burning or wearing down due to lack of water.

The control cabinet of the machine features an arm-mounted design, allowing operators to move it freely as needed for viewing and adjusting equipment parameters from different angles. To prevent the stone from being scratched during processing, white rubber strips are placed beside the guide rails to protect the integrity of the stone's straight edge.

The Yongtao Stone Edge Chamfering Machine is not only advanced in performance and easy to operate but also focuses on ease of maintenance. Its simple and reasonable structural design makes the equipment easy to maintain, providing strong support for the smooth operation of daily production.

This equipment is mainly used for straight edge rough grinding and polishing, followed by 45-degree chamfer rough grinding and polishing on materials such as marble, granite, and engineered stone. The one-time processing approach not only ensures processing accuracy but also enhances production efficiency, reducing the complexity of multiple operations.

Whether in architectural decoration, countertop processing, or craft production, the Yongtao Stone Edge Chamfering Machine can meet various production demands with its efficient and precise processing capabilities, making it an ideal piece of equipment in the stone processing industry.

The design and manufacturing of the Yongtao Marble Straight Edge Chamfering Machine incorporate the most advanced processing technology, ensuring

Parameter:

Serial | Name | Unit | Parameter |

1 | Number of rough grind wheel | Unit | 1 |

2 | Motor power of rough grind wheel | Kw | 3 |

3 | Number of polishing wheel | unit | 6 |

4 | Diameter of polishing wheel | mm | 125 |

5 | Motor power of polishing wheel | Kw | 3X3 |

6 | Number of rough grind bottom wheel | uint | 2 |

7 | Motor power of rough grind bottom wheel | Kw | 3 |

8 | Number of polishing bottom wheel | unit | 6 |

9 | Diameter of polishing bottom wheel | mm | 125 |

10 | Motor power of polishing bottom wheel | Kw | 2.2X3 |

11 | Workable width | mm | 80-800 |

12 | Workable thickness | mm | 10-60 |

13 | Workable speed | m/min | 1—5.0 |

14 | Total power | Kw | 27.55 |

15 | Power consumption | Kw/H | 25 |

16 | Water consumption | L/min | 500 |

17 | External size | a×b×h | 5.20×2.00×1.80 |

18 | Weight(about) | T | 4 |

The Stone Straight Edge Chamfering Machine is the latest high-performance stone processing machinery developed by Yongtao Machinery, specifically designed for processing hard materials such as marble, granite, and engineered stone. This equipment combines straight edge polishing and 45-degree chamfer polishing into one, allowing for efficient rough grinding and fine polishing in a single process. This significantly enhances production efficiency, making it the top choice for stone processing companies seeking excellent economic benefits.

The Yongtao Stone Straight Edge Chamfering Polishing Machine is suitable for processing various stones such as marble, granite, and engineered stone. The equipment supports material processing widths ranging from a minimum of 80mm to a maximum of 800mm, catering to a wide range of processing dimensions, demonstrating strong adaptability.

The machine adopts an advanced design concept, completing the processes of straight edge rough grinding, polishing, and 45-degree chamfer rough grinding, and polishing in one go. This significantly reduces processing time, offering fast processing speeds and excellent results, thereby markedly improving production line efficiency.

The equipment processes materials laid flat, with materials entering from the right side of the machine and exiting from the left after processing. The processing width is adjusted using an electric baffle, and the stainless steel water shield effectively prevents splashing, enhancing the cleanliness of the operating environment.

The Yongtao Granite Straight Edge Chamfering Machine is equipped with 1 straight edge rough grinding head and 6 straight edge polishing heads, along with 2 chamfer rough grinding heads and 6 chamfer polishing heads. Each grinding head is equipped with a water outlet to ensure sufficient water flow during processing, preventing the material from burning or wearing down due to lack of water.

The control cabinet of the machine features an arm-mounted design, allowing operators to move it freely as needed for viewing and adjusting equipment parameters from different angles. To prevent the stone from being scratched during processing, white rubber strips are placed beside the guide rails to protect the integrity of the stone's straight edge.

The Yongtao Stone Edge Chamfering Machine is not only advanced in performance and easy to operate but also focuses on ease of maintenance. Its simple and reasonable structural design makes the equipment easy to maintain, providing strong support for the smooth operation of daily production.

This equipment is mainly used for straight edge rough grinding and polishing, followed by 45-degree chamfer rough grinding and polishing on materials such as marble, granite, and engineered stone. The one-time processing approach not only ensures processing accuracy but also enhances production efficiency, reducing the complexity of multiple operations.

Whether in architectural decoration, countertop processing, or craft production, the Yongtao Stone Edge Chamfering Machine can meet various production demands with its efficient and precise processing capabilities, making it an ideal piece of equipment in the stone processing industry.

The design and manufacturing of the Yongtao Marble Straight Edge Chamfering Machine incorporate the most advanced processing technology, ensuring

Parameter:

Serial | Name | Unit | Parameter |

1 | Number of rough grind wheel | Unit | 1 |

2 | Motor power of rough grind wheel | Kw | 3 |

3 | Number of polishing wheel | unit | 6 |

4 | Diameter of polishing wheel | mm | 125 |

5 | Motor power of polishing wheel | Kw | 3X3 |

6 | Number of rough grind bottom wheel | uint | 2 |

7 | Motor power of rough grind bottom wheel | Kw | 3 |

8 | Number of polishing bottom wheel | unit | 6 |

9 | Diameter of polishing bottom wheel | mm | 125 |

10 | Motor power of polishing bottom wheel | Kw | 2.2X3 |

11 | Workable width | mm | 80-800 |

12 | Workable thickness | mm | 10-60 |

13 | Workable speed | m/min | 1—5.0 |

14 | Total power | Kw | 27.55 |

15 | Power consumption | Kw/H | 25 |

16 | Water consumption | L/min | 500 |

17 | External size | a×b×h | 5.20×2.00×1.80 |

18 | Weight(about) | T | 4 |