Yongtao Machinery has recently launched a 6-head granite edge profile machine, a high-performance stone edge molding machine designed specifically for profiling and polishing the edges of natural and engineered stone. This equipment integrates both rough grinding (shaping) and polishing functions, making it an ideal choice for enhancing production efficiency and creating significant economic benefits with its compact structure and stable operation.

Yongtao Machinery has recently launched a 6-head granite edge profile machine, a high-performance stone edge molding machine designed specifically for profiling and polishing the edges of natural and engineered stone. This equipment integrates both rough grinding (shaping) and polishing functions, making it an ideal choice for enhancing production efficiency and creating significant economic benefits with its compact structure and stable operation.

The 6-head marble edge profile machine features an advanced design concept, with a compact overall structure that ensures high stability during operation. The moulding section employs a fixed-depth grinding method to ensure processing accuracy and consistency. The polishing section is equipped with an automatic feed control and compensation system, effectively preventing impact force during feeding, thus avoiding stone damage and significantly improving production efficiency.

The machine is equipped with 2 molding heads and 4 polishing heads, allowing simultaneous edge molding and polishing of stone materials. The moulding wheels are made of high-strength diamond grinding wheels, ensuring both the aesthetic quality of the edge profile and the durability of the wheels. The polishing wheels are made of resin material, providing a fine and smooth polishing effect. Each molding and polishing head is equipped with an adjustable micro-adjustment structure, allowing manual adjustment of each wheel's in and out position, as well as electric adjustment of the size range of the guide plate. The maximum processing width is 800mm, and the minimum is 80mm, making it suitable for various stone sizes.

Depending on the processing needs, a set of wheels must be replaced for each moulding and polishing operation. Each set includes 6 individual wheels, and the replacement process is simple and quick, requiring only manual operation, which greatly reduces machine downtime and improves production efficiency.

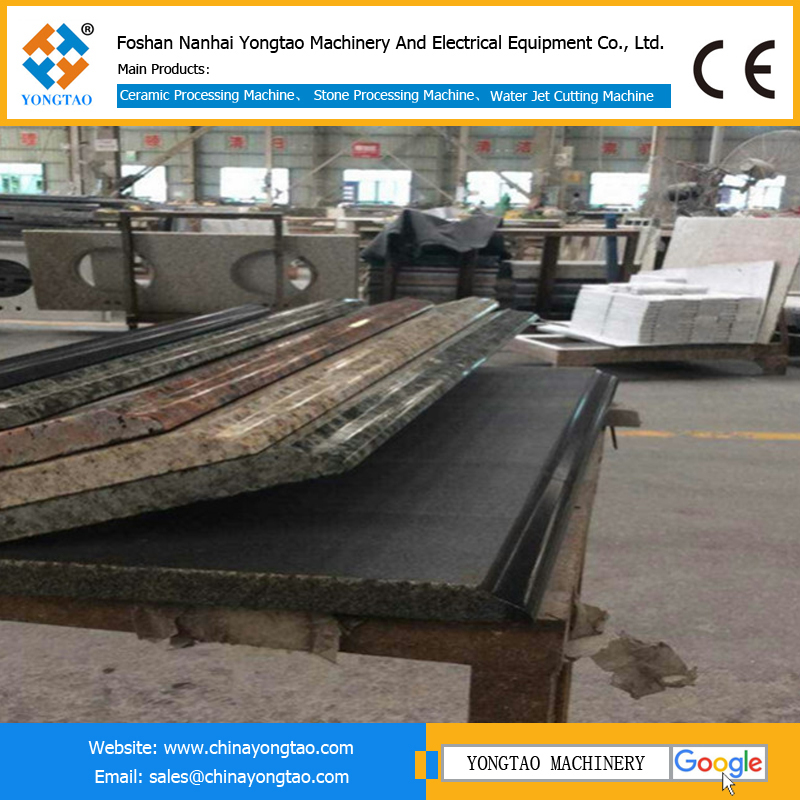

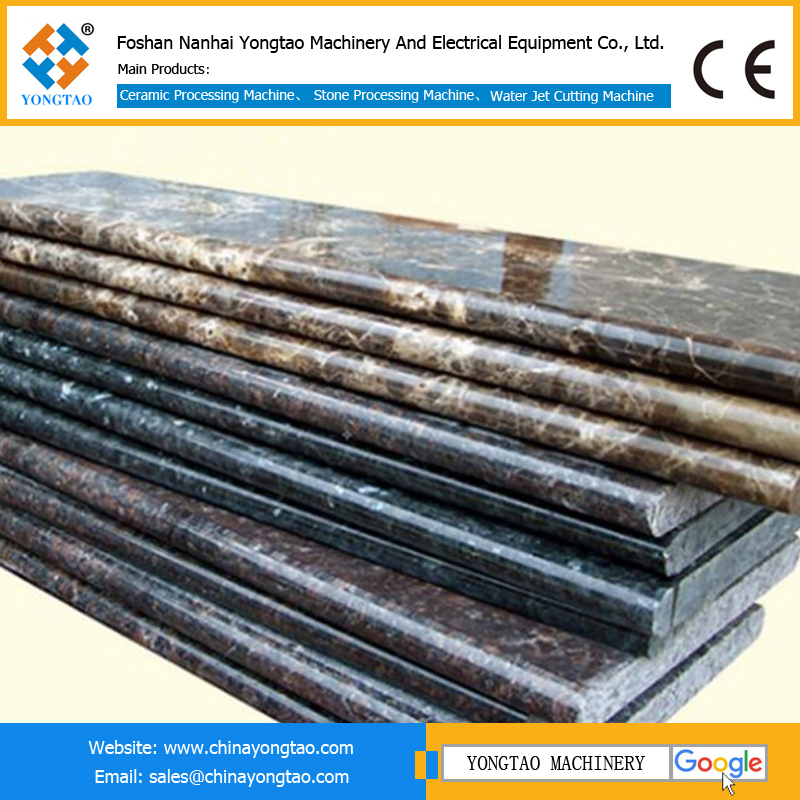

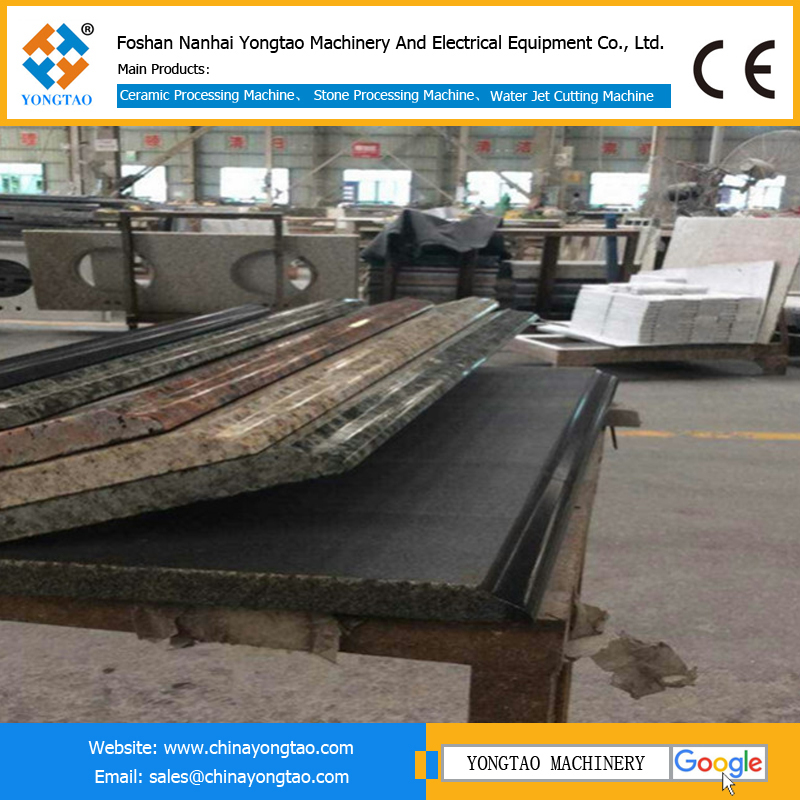

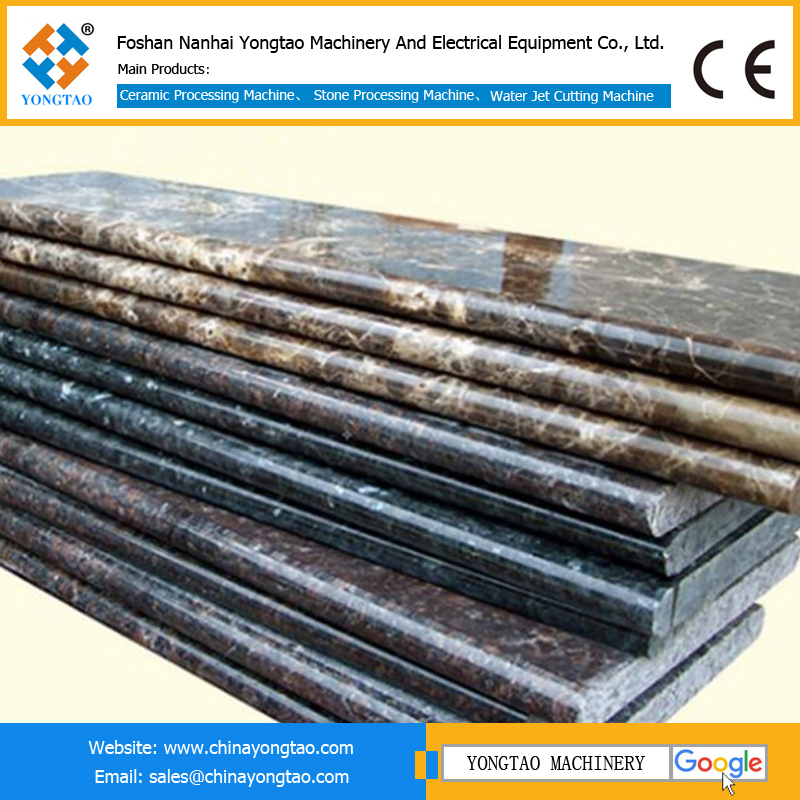

This machine is suitable for processing various stone materials, such as marble and granite, and can produce a variety of complex edge profiles, including stone stair handrail edges, OGEE edges, granite bullnose edges, French edges, and European edges, offering customers a diversified range of product choices.

The machine is equipped with a red conveyor belt divided into upper and lower layers. The upper belt firmly secures the granite stone, preventing material displacement during processing, thereby ensuring processing accuracy and product quality.

The machine features a swing-arm control box design, making it easier for operators to view and adjust equipment parameters. Each motor is equipped with an independent control switch, facilitating start-up, shutdown, and maintenance, enhancing operational convenience and safety.

The materials for the 6 lifting structures of the machine are made of high-strength cast iron, ensuring the durability of the equipment and improving processing accuracy and stability.

Yongtao Machinery's 6-head stone edge profile machine, with its ability to process various shapes, high efficiency, and precision, has become an indispensable piece of equipment in the stone processing industry. Its flexible design and user-friendly operation help users meet different stone processing needs while significantly improving production efficiency and delivering notable economic benefits to enterprises.

Parameter:

Serial | Name | Unit | Parameter |

1 | Number of shape wheel | Unit | 2 |

2 | Motor power of shape wheel | Kw | 4 |

3 | Diameter of shape wheel | mm | 150-200 |

4 | Number of polishing wheel | unit | 4 |

5 | Motor power of polishing wheel | Kw | 4 |

6 | Diameter of polishing wheel | mm | 150-200 |

7 | Workable thickness | mm | 10-80 |

8 | Workable width | mm | 80-800 |

9 | Workable speed | m/min | 0.3—3.0 |

10 | Total power | Kw | 29.53 |

12 | Power consumption | Kw | 25 |

13 | Water consumption(about) | L/min | 450 |

14 | External size | a×b×h | 4.50×2.00×1.80 |

15 | Weight(about) | T | 4 |

Yongtao Machinery has recently launched a 6-head granite edge profile machine, a high-performance stone edge molding machine designed specifically for profiling and polishing the edges of natural and engineered stone. This equipment integrates both rough grinding (shaping) and polishing functions, making it an ideal choice for enhancing production efficiency and creating significant economic benefits with its compact structure and stable operation.

The 6-head marble edge profile machine features an advanced design concept, with a compact overall structure that ensures high stability during operation. The moulding section employs a fixed-depth grinding method to ensure processing accuracy and consistency. The polishing section is equipped with an automatic feed control and compensation system, effectively preventing impact force during feeding, thus avoiding stone damage and significantly improving production efficiency.

The machine is equipped with 2 molding heads and 4 polishing heads, allowing simultaneous edge molding and polishing of stone materials. The moulding wheels are made of high-strength diamond grinding wheels, ensuring both the aesthetic quality of the edge profile and the durability of the wheels. The polishing wheels are made of resin material, providing a fine and smooth polishing effect. Each molding and polishing head is equipped with an adjustable micro-adjustment structure, allowing manual adjustment of each wheel's in and out position, as well as electric adjustment of the size range of the guide plate. The maximum processing width is 800mm, and the minimum is 80mm, making it suitable for various stone sizes.

Depending on the processing needs, a set of wheels must be replaced for each moulding and polishing operation. Each set includes 6 individual wheels, and the replacement process is simple and quick, requiring only manual operation, which greatly reduces machine downtime and improves production efficiency.

This machine is suitable for processing various stone materials, such as marble and granite, and can produce a variety of complex edge profiles, including stone stair handrail edges, OGEE edges, granite bullnose edges, French edges, and European edges, offering customers a diversified range of product choices.

The machine is equipped with a red conveyor belt divided into upper and lower layers. The upper belt firmly secures the granite stone, preventing material displacement during processing, thereby ensuring processing accuracy and product quality.

The machine features a swing-arm control box design, making it easier for operators to view and adjust equipment parameters. Each motor is equipped with an independent control switch, facilitating start-up, shutdown, and maintenance, enhancing operational convenience and safety.

The materials for the 6 lifting structures of the machine are made of high-strength cast iron, ensuring the durability of the equipment and improving processing accuracy and stability.

Yongtao Machinery's 6-head stone edge profile machine, with its ability to process various shapes, high efficiency, and precision, has become an indispensable piece of equipment in the stone processing industry. Its flexible design and user-friendly operation help users meet different stone processing needs while significantly improving production efficiency and delivering notable economic benefits to enterprises.

Parameter:

Serial | Name | Unit | Parameter |

1 | Number of shape wheel | Unit | 2 |

2 | Motor power of shape wheel | Kw | 4 |

3 | Diameter of shape wheel | mm | 150-200 |

4 | Number of polishing wheel | unit | 4 |

5 | Motor power of polishing wheel | Kw | 4 |

6 | Diameter of polishing wheel | mm | 150-200 |

7 | Workable thickness | mm | 10-80 |

8 | Workable width | mm | 80-800 |

9 | Workable speed | m/min | 0.3—3.0 |

10 | Total power | Kw | 29.53 |

12 | Power consumption | Kw | 25 |

13 | Water consumption(about) | L/min | 450 |

14 | External size | a×b×h | 4.50×2.00×1.80 |

15 | Weight(about) | T | 4 |