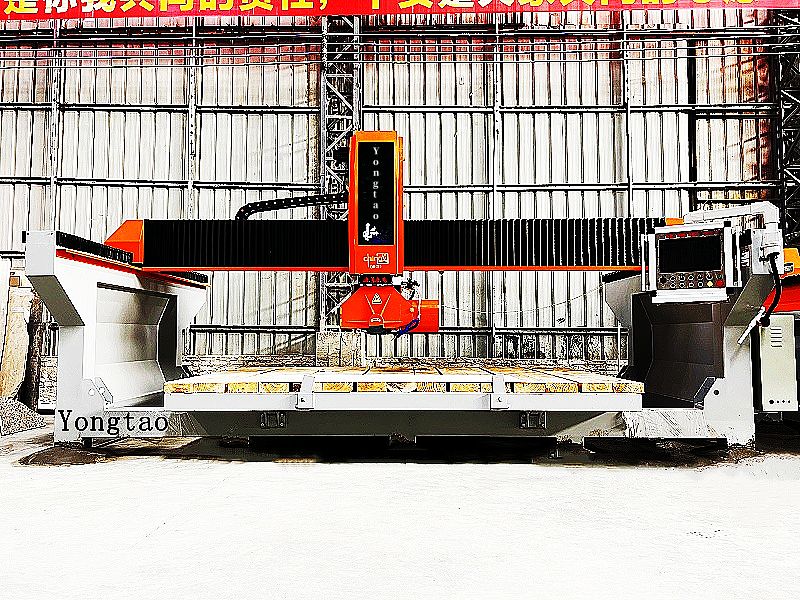

The YSQZ-3200-5L 5-axis CNC granite cutting machine developed by Yongtao Machinery is specifically designed for stone processing factories to meet various complex cutting needs. This high-efficiency, multifunctional granite bridge saw machine adopts an innovative five-axis design, supporting a variety of cutting modes such as round, oval, 45-degree, L-shaped countertops, and sink holes, making it an ideal choice in the stone cutting machine market.

The YSQZ-3200-5L 5-axis CNC granite cutting machine developed by Yongtao Machinery is specifically designed for stone processing factories to meet various complex cutting needs. This high-efficiency, multifunctional granite bridge saw machine adopts an innovative five-axis design, supporting a variety of cutting modes such as round, oval, 45-degree, L-shaped countertops, and sink holes, making it an ideal choice in the stone cutting machine market.

Equipped with five axes: X, Y, Z, A, and C, the YSQZ-3200-5L enables multi-axis three-dimensional cutting. The A-axis can automatically rotate from 0 to 90°, while the C-axis supports full rotation from 0 to 360°, making it particularly suitable for intricate stone cutting tasks. This machine features a high-precision RV reducer to ensure cutting accuracy, especially for processing hard materials like granite.

This equipment includes an automatic tilting tabletop function, significantly reducing the labor intensity of manual operations. Particularly in large stone cutting scenarios, the tilted table design facilitates easier unloading, greatly improving work efficiency. This design not only enhances operational convenience but also effectively saves processing time, establishing itself as a vital granite cutting machine in the industry.

The intelligent operating system of the YSQZ-3200-5L granite wet saw includes features like intelligent photo layout and automatic thickness measurement, allowing for precise control of tool positions. The operation is simple, as users can easily complete complex cuts by inputting the necessary data. Additionally, the system supports multiple language switches, providing a convenient global operating experience.

This device utilizes a hydraulic tilting power system, with hydraulic cylinders as the core power source, offering high redundancy and adaptability. The machine supports four-sided beveling (0-90 degrees), making it suitable for various stones, including applications for small granite cutting machines. Whether processing sintered stones, large ceramic slabs, quartz stones, or small marble cutting machines, the equipment demonstrates exceptional cutting performance.

The YSQZ-3200-5L uses high-quality imported spindles and a five-axis control system, further enhancing cutting stability and precision. The combination of Yaskawa servo drives, imported gears, racks, and rail systems from Taiwan not only boosts the machine’s operational efficiency but also significantly extends its service life, making it a top choice among granite bridge saw options.

Equipped with a linear infrared emitter that displays the cutting path in real-time, the YSQZ-3200-5L ensures precise positioning during the cutting process. The 360-degree omnidirectional swing function and the 85-degree tilting tabletop design facilitate easier loading and unloading, reducing manual intervention and improving overall work efficiency. This makes it an ideal granite bridge saw for sale in the market.

The YSQZ-3200-5L is widely used for processing sintered stones, large ceramic slabs, quartz stones, and is also compatible with small stone cutting machine tasks. Its outstanding cutting performance has gained popularity among customers both domestically and internationally, making it a favored choice in the prefabricated building and home decoration materials industry.

This versatile small stone cutter is perfect for both large projects and intricate details, ensuring precision and efficiency in every cut. With its robust design and advanced features, the YSQZ-3200-5L stands out as a leading solution in the realm of granite saw technologies.

In summary, the YSQZ-3200-5L five-axis granite bridge saw not only meets the needs of various stone processing tasks but also enhances efficiency and precision. With its advanced features and reliable performance, it has become a favored choice in the stone cutting industry, promising to elevate the capabilities of stone processing operations.

Technical Parameters:

Serial Number | Name | Parameters |

1 | X-axis working stroke | 0 - 3000mm |

2 | Y-axis working stroke | 0 - 2000mm |

3 | Z-axis working stroke | 0 - 300mm |

4 | A-axis working stroke | 0 - 90 degrees |

5 | C-axis rotation angle | 0 - 360 degrees |

6 | Spindle power | 15 - 22kw |

7 | Spindle speed | 0 - 3000 revolutions/minute |

8 | Cutting saw blade size | φ300 - 450mm |

9 | Control system | Taiwan |

10 | Servo driver | Weikang |

11 | Rack/Guide rail | Taiwan |

12 | Suction cup function | Yes (Optional) |

13 | Tool setting function | Yes (Optional) |

14 | Photo function | Yes (Optional) |

15 | Thickness measurement function | Yes (Optional) |

16 | Total power of the whole machine | 18 - 25kw |

17 | Overall dimensions of the whole machine (X, Y, Z) | 5600x3300x2800mm |

18 | Weight | Approximately 4500kg |

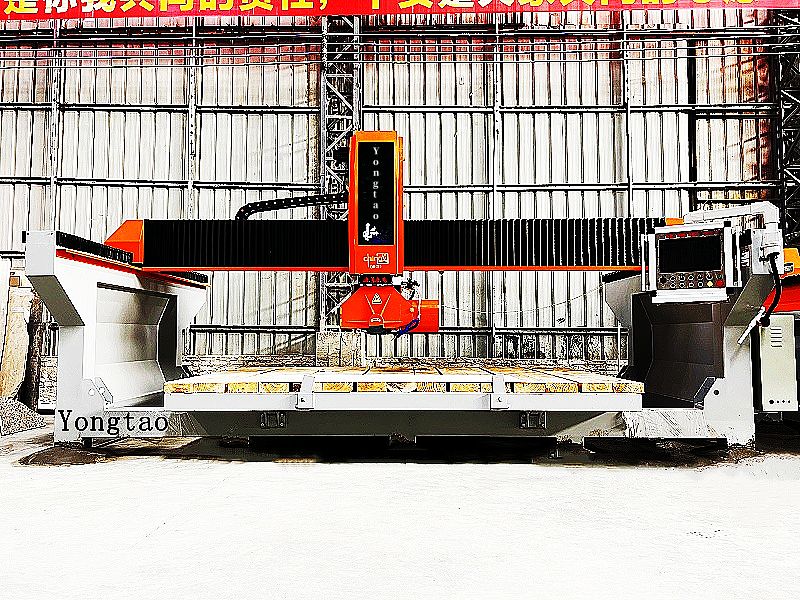

The YSQZ-3200-5L 5-axis CNC granite cutting machine developed by Yongtao Machinery is specifically designed for stone processing factories to meet various complex cutting needs. This high-efficiency, multifunctional granite bridge saw machine adopts an innovative five-axis design, supporting a variety of cutting modes such as round, oval, 45-degree, L-shaped countertops, and sink holes, making it an ideal choice in the stone cutting machine market.

Equipped with five axes: X, Y, Z, A, and C, the YSQZ-3200-5L enables multi-axis three-dimensional cutting. The A-axis can automatically rotate from 0 to 90°, while the C-axis supports full rotation from 0 to 360°, making it particularly suitable for intricate stone cutting tasks. This machine features a high-precision RV reducer to ensure cutting accuracy, especially for processing hard materials like granite.

This equipment includes an automatic tilting tabletop function, significantly reducing the labor intensity of manual operations. Particularly in large stone cutting scenarios, the tilted table design facilitates easier unloading, greatly improving work efficiency. This design not only enhances operational convenience but also effectively saves processing time, establishing itself as a vital granite cutting machine in the industry.

The intelligent operating system of the YSQZ-3200-5L granite wet saw includes features like intelligent photo layout and automatic thickness measurement, allowing for precise control of tool positions. The operation is simple, as users can easily complete complex cuts by inputting the necessary data. Additionally, the system supports multiple language switches, providing a convenient global operating experience.

This device utilizes a hydraulic tilting power system, with hydraulic cylinders as the core power source, offering high redundancy and adaptability. The machine supports four-sided beveling (0-90 degrees), making it suitable for various stones, including applications for small granite cutting machines. Whether processing sintered stones, large ceramic slabs, quartz stones, or small marble cutting machines, the equipment demonstrates exceptional cutting performance.

The YSQZ-3200-5L uses high-quality imported spindles and a five-axis control system, further enhancing cutting stability and precision. The combination of Yaskawa servo drives, imported gears, racks, and rail systems from Taiwan not only boosts the machine’s operational efficiency but also significantly extends its service life, making it a top choice among granite bridge saw options.

Equipped with a linear infrared emitter that displays the cutting path in real-time, the YSQZ-3200-5L ensures precise positioning during the cutting process. The 360-degree omnidirectional swing function and the 85-degree tilting tabletop design facilitate easier loading and unloading, reducing manual intervention and improving overall work efficiency. This makes it an ideal granite bridge saw for sale in the market.

The YSQZ-3200-5L is widely used for processing sintered stones, large ceramic slabs, quartz stones, and is also compatible with small stone cutting machine tasks. Its outstanding cutting performance has gained popularity among customers both domestically and internationally, making it a favored choice in the prefabricated building and home decoration materials industry.

This versatile small stone cutter is perfect for both large projects and intricate details, ensuring precision and efficiency in every cut. With its robust design and advanced features, the YSQZ-3200-5L stands out as a leading solution in the realm of granite saw technologies.

In summary, the YSQZ-3200-5L five-axis granite bridge saw not only meets the needs of various stone processing tasks but also enhances efficiency and precision. With its advanced features and reliable performance, it has become a favored choice in the stone cutting industry, promising to elevate the capabilities of stone processing operations.

Technical Parameters:

Serial Number | Name | Parameters |

1 | X-axis working stroke | 0 - 3000mm |

2 | Y-axis working stroke | 0 - 2000mm |

3 | Z-axis working stroke | 0 - 300mm |

4 | A-axis working stroke | 0 - 90 degrees |

5 | C-axis rotation angle | 0 - 360 degrees |

6 | Spindle power | 15 - 22kw |

7 | Spindle speed | 0 - 3000 revolutions/minute |

8 | Cutting saw blade size | φ300 - 450mm |

9 | Control system | Taiwan |

10 | Servo driver | Weikang |

11 | Rack/Guide rail | Taiwan |

12 | Suction cup function | Yes (Optional) |

13 | Tool setting function | Yes (Optional) |

14 | Photo function | Yes (Optional) |

15 | Thickness measurement function | Yes (Optional) |

16 | Total power of the whole machine | 18 - 25kw |

17 | Overall dimensions of the whole machine (X, Y, Z) | 5600x3300x2800mm |

18 | Weight | Approximately 4500kg |