Yongtao L-Shaped Double-Blade Stone Cutting Machine is a professional device designed specifically for the stone processing industry, primarily used for cutting stone corners and edges. Its unique design and features enable outstanding performance when working with materials such as artificial stone, quartz stone, marble, and more, significantly enhancing processing efficiency and precision.

Yongtao L-Shaped Double-Blade Stone Cutting Machine is a professional device designed specifically for the stone processing industry, primarily used for cutting stone corners and edges. Its unique design and features enable outstanding performance when working with materials such as artificial stone, quartz stone, marble, and more, significantly enhancing processing efficiency and precision.

The Yongtao L-Shaped Double-Blade Artificial Stone Cutting Machine is equipped with two blades: one for horizontal cutting and the other for vertical cutting. This design allows the machine to perform cuts in both directions in a single operation, easily removing excess material from the stone to achieve the desired L-shaped or grooved structure. This design not only reduces the complexity of manual operations but also improves production efficiency.

Before using this machine, it's typically necessary to first cut the large slab material into the appropriate size using a manual stone cutting machine or infrared stone cutting machine. Then, the cut stone is placed into the Yongtao L-Shaped Double-Blade Cutting Machine for fine cutting, resulting in smaller pieces. These smaller pieces can be further processed, such as by using a fully automatic stone molding machine for grinding, to create ideal corner or edge shapes.

To ensure the accuracy of stone molding, a template is placed under the artificial stone for fixation during processing. The use of such a template not only ensures shape consistency but also allows for the simultaneous processing of multiple corner shapes, greatly improving production efficiency. Daily production can reach up to several kilometers, meeting large-scale production demands.

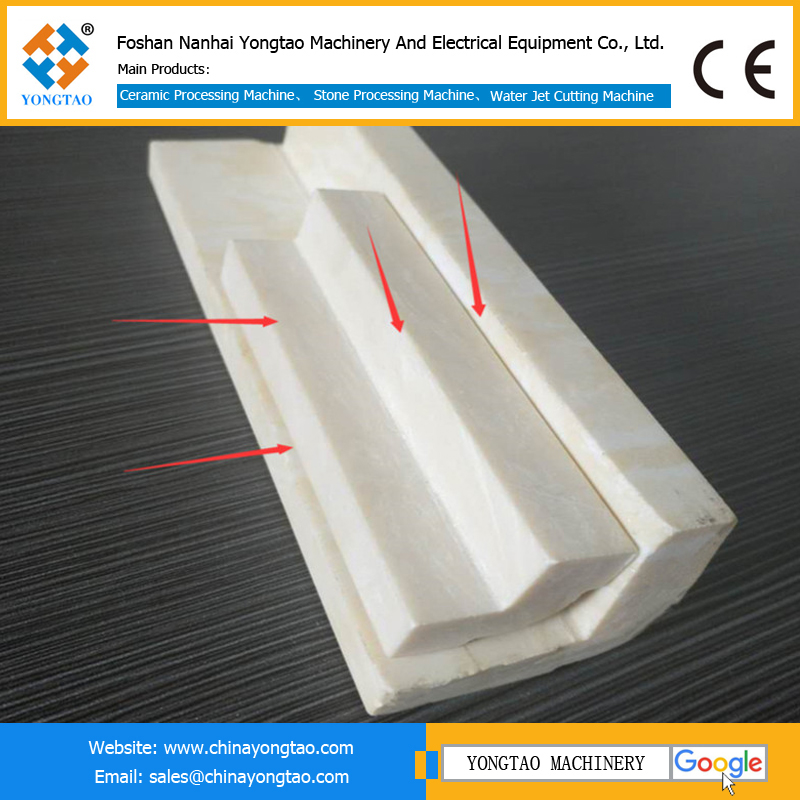

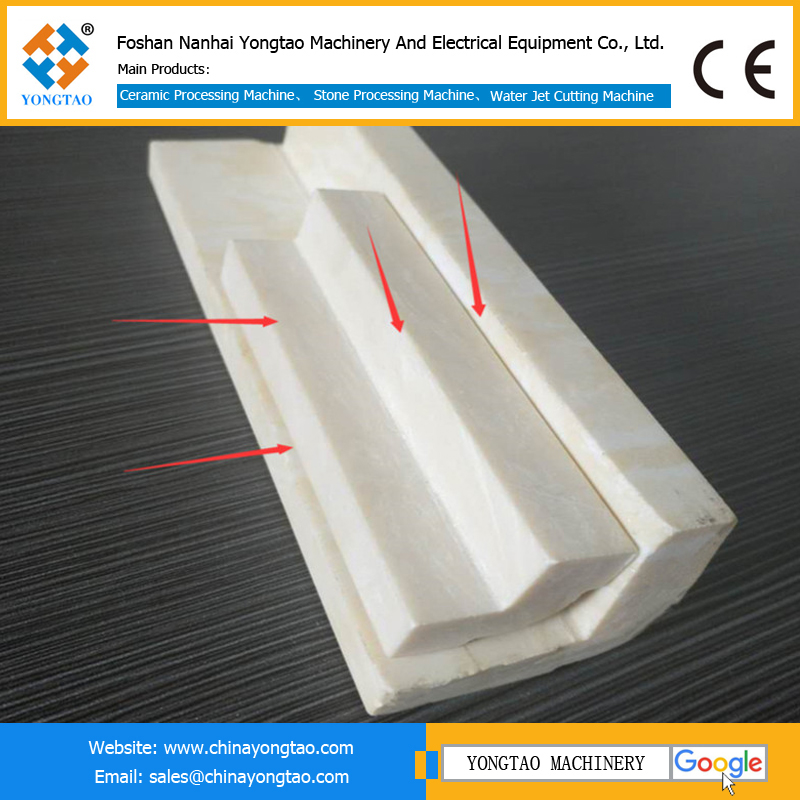

The machine can also be used for L-shaped groove processing of stone. By performing both horizontal and vertical cuts, a small portion of the stone can be quickly removed, forming a grooved structure. This type of groove is commonly used in specific decorative or architectural applications and can be polished and finished to meet final product standards.

In addition to groove processing, the Yongtao L-Shaped Double-Blade Quartz Stone Cutting Machine can cut a rectangular stone into smaller rectangular pieces, leaving an L-shaped structure on the outside. For L-shaped stones that require further processing, such as for making corners or edges, they can be sent to a stone moulding machine for secondary processing. If further shaping is not needed, a manual polishing of the cross-section inside the L-shape is sufficient to complete the final product.

1. Artificial Stone

2. Engineered Stone

3. Quartz Stone

4. Marble

1. Artificial Stone Corners

2. Stone Edges

Horizontal and vertical blade cutting to remove a small section.

The Yongtao L-Shaped Double-Blade Marble Cutting Machine, with its efficient and dual-blade design, has become an indispensable machine in the stone processing industry. Whether for large-scale production or projects with high precision requirements, it is capable of meeting user needs, enabling high-quality and efficient processing outcomes.

Technical Parameters | Details |

Transmission Motor Power | 0.75 kw |

Main Motor Power | 5.5 kw * 2 |

Blade Size | Φ200-250 mm |

Belt Width | 200 mm |

Machine Dimensions | 2.4 * 1.1 * 1.65 m |

Weight | 600 kg |

Spindle Diameter | 60 mm |

Voltage | 380 V |

Yongtao L-Shaped Double-Blade Stone Cutting Machine is a professional device designed specifically for the stone processing industry, primarily used for cutting stone corners and edges. Its unique design and features enable outstanding performance when working with materials such as artificial stone, quartz stone, marble, and more, significantly enhancing processing efficiency and precision.

The Yongtao L-Shaped Double-Blade Artificial Stone Cutting Machine is equipped with two blades: one for horizontal cutting and the other for vertical cutting. This design allows the machine to perform cuts in both directions in a single operation, easily removing excess material from the stone to achieve the desired L-shaped or grooved structure. This design not only reduces the complexity of manual operations but also improves production efficiency.

Before using this machine, it's typically necessary to first cut the large slab material into the appropriate size using a manual stone cutting machine or infrared stone cutting machine. Then, the cut stone is placed into the Yongtao L-Shaped Double-Blade Cutting Machine for fine cutting, resulting in smaller pieces. These smaller pieces can be further processed, such as by using a fully automatic stone molding machine for grinding, to create ideal corner or edge shapes.

To ensure the accuracy of stone molding, a template is placed under the artificial stone for fixation during processing. The use of such a template not only ensures shape consistency but also allows for the simultaneous processing of multiple corner shapes, greatly improving production efficiency. Daily production can reach up to several kilometers, meeting large-scale production demands.

The machine can also be used for L-shaped groove processing of stone. By performing both horizontal and vertical cuts, a small portion of the stone can be quickly removed, forming a grooved structure. This type of groove is commonly used in specific decorative or architectural applications and can be polished and finished to meet final product standards.

In addition to groove processing, the Yongtao L-Shaped Double-Blade Quartz Stone Cutting Machine can cut a rectangular stone into smaller rectangular pieces, leaving an L-shaped structure on the outside. For L-shaped stones that require further processing, such as for making corners or edges, they can be sent to a stone moulding machine for secondary processing. If further shaping is not needed, a manual polishing of the cross-section inside the L-shape is sufficient to complete the final product.

1. Artificial Stone

2. Engineered Stone

3. Quartz Stone

4. Marble

1. Artificial Stone Corners

2. Stone Edges

Horizontal and vertical blade cutting to remove a small section.

The Yongtao L-Shaped Double-Blade Marble Cutting Machine, with its efficient and dual-blade design, has become an indispensable machine in the stone processing industry. Whether for large-scale production or projects with high precision requirements, it is capable of meeting user needs, enabling high-quality and efficient processing outcomes.

Technical Parameters | Details |

Transmission Motor Power | 0.75 kw |

Main Motor Power | 5.5 kw * 2 |

Blade Size | Φ200-250 mm |

Belt Width | 200 mm |

Machine Dimensions | 2.4 * 1.1 * 1.65 m |

Weight | 600 kg |

Spindle Diameter | 60 mm |

Voltage | 380 V |