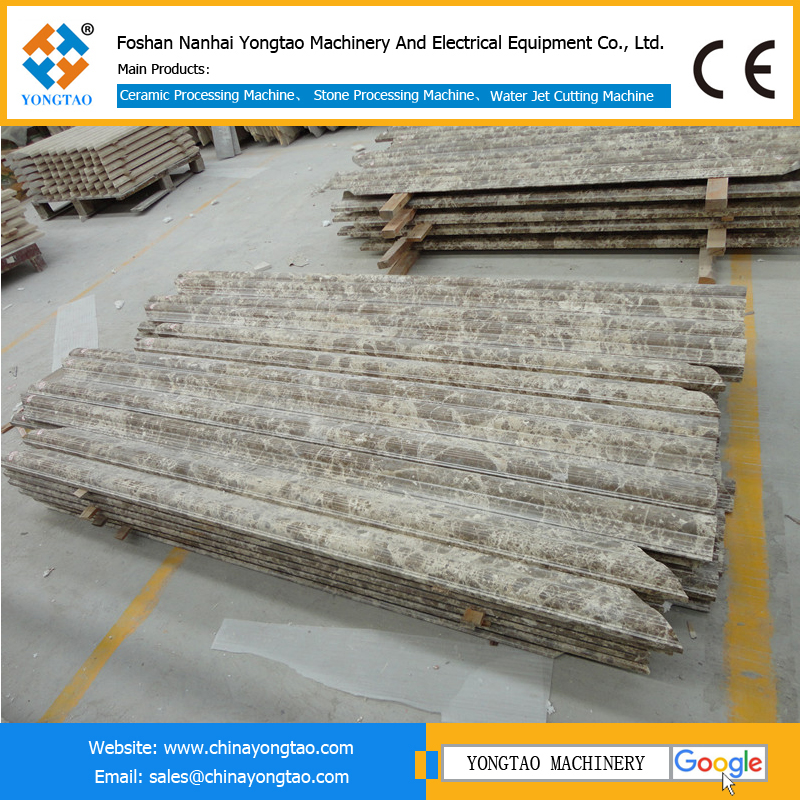

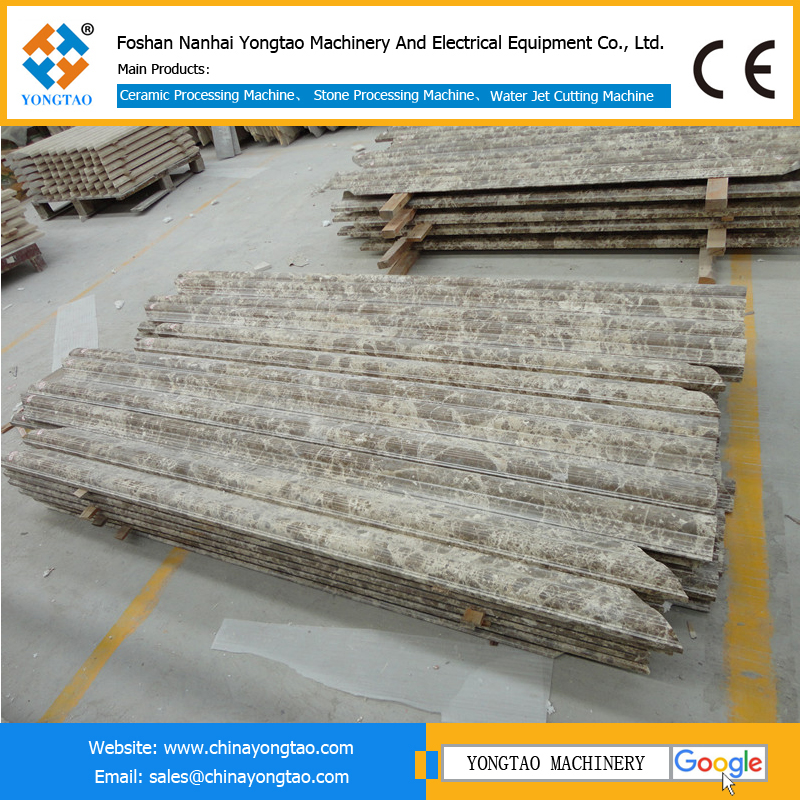

The high efficiency of the Yongtao 8-Head Stone Molding Machine makes it an ideal choice for stone processing plants, especially in mass production scenarios. Common stone profile sizes include 6cm, 8cm, 10cm, 12cm, and 15cm in various dimensions. Depending on material thickness and profile depth, the machine can process 200-300 meters of stone profiles within 8 hours.

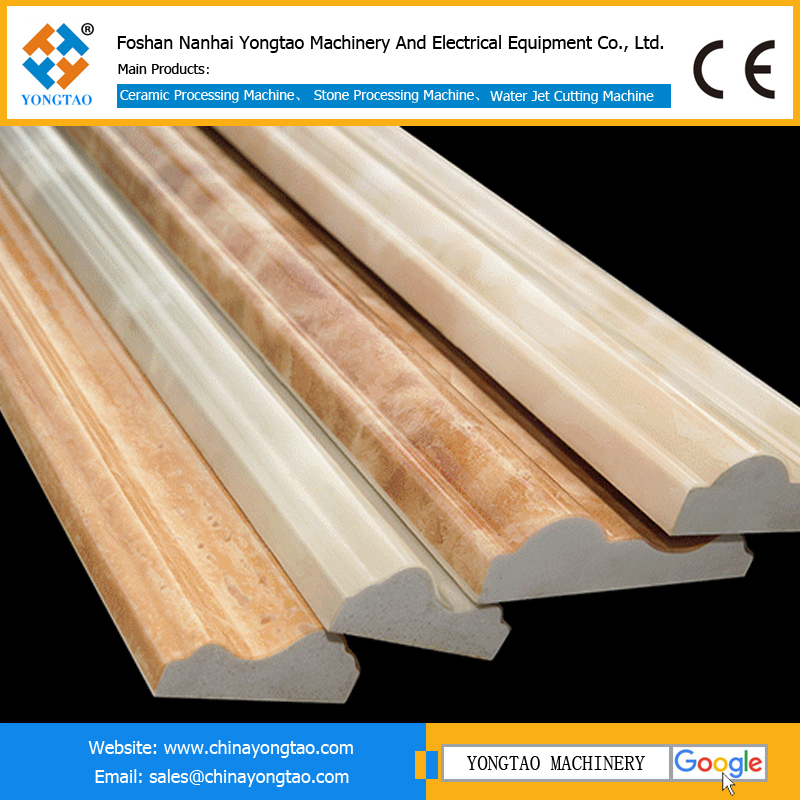

The Yongtao 8-Head Stone Molding Machine is a specialized machine designed for processing stone pencil edges and bullnose profiles. It boasts excellent processing capabilities, achieving a glossiness of up to 90 degrees or more on bullnose profiles, with some materials even reaching over 100 degrees. The machine is equipped with three shaping units at the front and five polishing units at the rear, along with a 2.5-meter-long rail at both the front and back. The shaping main motor power is 7.5KW, and the polishing main motor power is 5.5KW, with a total power exceeding 50KW. The machine has a total length of 10.5 meters, making it suitable for various batch production needs.

The Yongtao 8-Head Stone Profiling Machine stands out for its remarkable processing features, including fast processing speed, high glossiness, high productivity, low processing cost, and a high degree of automation. The machine is equipped with an automatic compensation system that adjusts the polishing wheels automatically as they wear down, ensuring that the wheels maintain close contact with the material during grinding, thus ensuring an outstanding polishing effect. In terms of processing speed, for a 10 cm wide and 3 cm thick slab, the machine can achieve a processing speed of 25-35 meters per hour, with a potential output of 200-300 meters in an 8-hour workday, demonstrating exceptional efficiency.

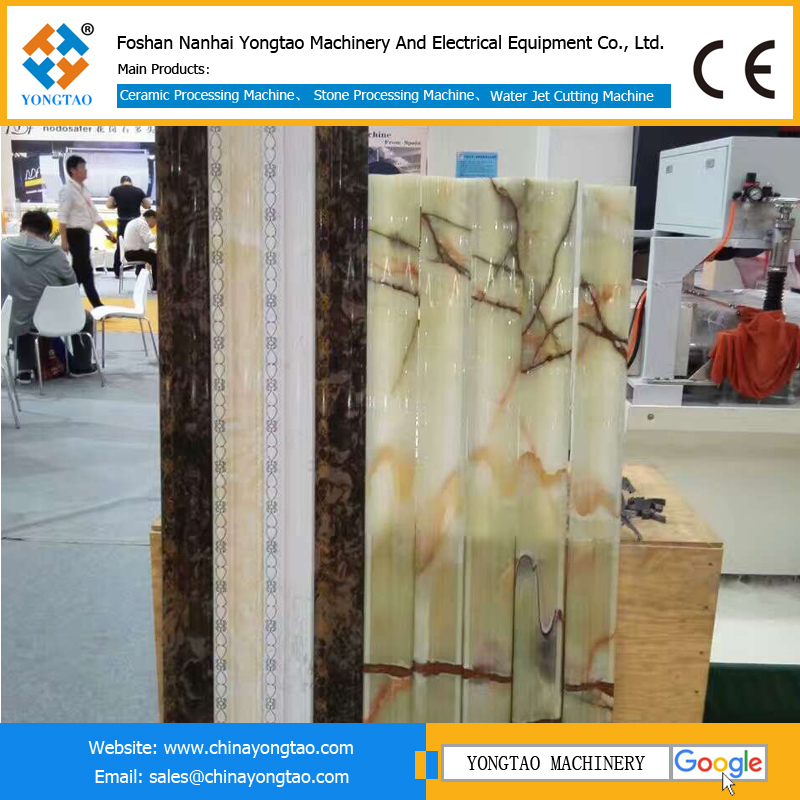

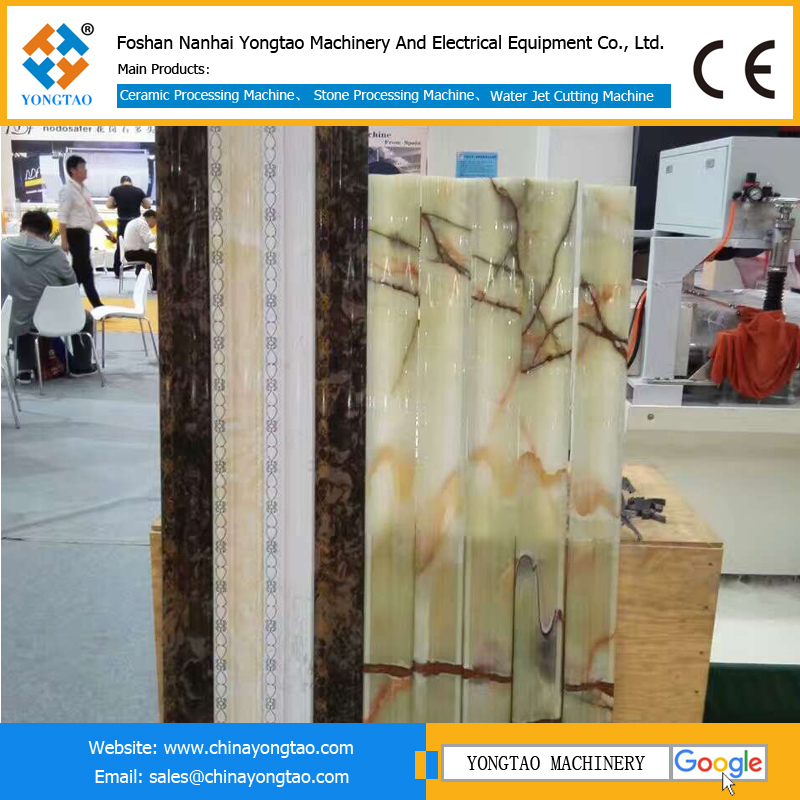

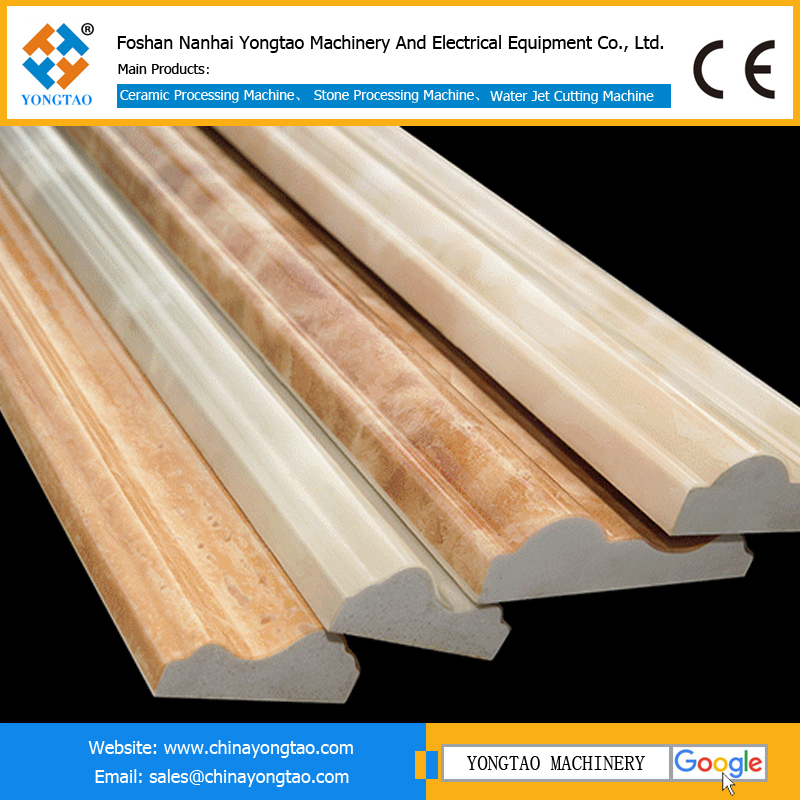

To achieve the best processing results, the Yongtao 8-Head Stone Profiling Polishing Machine uses different wheel materials. Electroplated wheels are used for moulding, resin polishing wheels for rough polishing, and sponge polishing wheels are employed to enhance the glossiness of pencil edges. This careful selection of materials ensures a high glossiness and excellent texture in the bullnose profiles. The stone machine is suitable for processing various materials, including ceramics, stone, marble, granite, and artificial stone, and is particularly effective in processing stone bullnose profiles.

The high efficiency of the Yongtao 8-Head Stone Moulding Machine makes it an ideal choice for stone processing plants, especially in mass production scenarios. Common stone profile sizes include 6cm, 8cm, 10cm, 12cm, and 15cm in various dimensions. Depending on material thickness and profile depth, the machine can process 200-300 meters of stone profiles within 8 hours. The processed profiles can achieve a glossiness of 90-120 degrees, with a smooth surface that requires no additional waxing, effortlessly achieving a reflective finish, ensuring excellent quality and visual appeal in the final product.

Parameter:

Serial | Name | Unit | Parameter |

1 | Number of shape wheel | Unit | 3 |

2 | Motor power of shape wheel | Kw | 7.5 |

3 | Diameter of shape wheel | mm | 180-200 |

4 | Number of polishing wheel | unit | 5 |

5 | Motor power of polishing wheel | Kw | 5.5 |

6 | Diameter of polishing wheel | mm | 150-220 |

7 | Max workable line width | mm | 250 |

8 | Workable width | mm | 30-400 |

9 | Workable thickness | mm | 10-70 |

10 | Workable speed | m/min | 0.3—3.0 |

11 | Total power | Kw | 58.63 |

12 | Power consumption | Kw | 50 |

13 | Water consumption(about) | L/min | 500 |

14 | External size | a×b×h | 10.30×2.00×1.80(m) |

15 | Weight(about) | T | 5 |

The Yongtao 8-Head Stone Molding Machine is a specialized machine designed for processing stone pencil edges and bullnose profiles. It boasts excellent processing capabilities, achieving a glossiness of up to 90 degrees or more on bullnose profiles, with some materials even reaching over 100 degrees. The machine is equipped with three shaping units at the front and five polishing units at the rear, along with a 2.5-meter-long rail at both the front and back. The shaping main motor power is 7.5KW, and the polishing main motor power is 5.5KW, with a total power exceeding 50KW. The machine has a total length of 10.5 meters, making it suitable for various batch production needs.

The Yongtao 8-Head Stone Profiling Machine stands out for its remarkable processing features, including fast processing speed, high glossiness, high productivity, low processing cost, and a high degree of automation. The machine is equipped with an automatic compensation system that adjusts the polishing wheels automatically as they wear down, ensuring that the wheels maintain close contact with the material during grinding, thus ensuring an outstanding polishing effect. In terms of processing speed, for a 10 cm wide and 3 cm thick slab, the machine can achieve a processing speed of 25-35 meters per hour, with a potential output of 200-300 meters in an 8-hour workday, demonstrating exceptional efficiency.

To achieve the best processing results, the Yongtao 8-Head Stone Profiling Polishing Machine uses different wheel materials. Electroplated wheels are used for moulding, resin polishing wheels for rough polishing, and sponge polishing wheels are employed to enhance the glossiness of pencil edges. This careful selection of materials ensures a high glossiness and excellent texture in the bullnose profiles. The stone machine is suitable for processing various materials, including ceramics, stone, marble, granite, and artificial stone, and is particularly effective in processing stone bullnose profiles.

The high efficiency of the Yongtao 8-Head Stone Moulding Machine makes it an ideal choice for stone processing plants, especially in mass production scenarios. Common stone profile sizes include 6cm, 8cm, 10cm, 12cm, and 15cm in various dimensions. Depending on material thickness and profile depth, the machine can process 200-300 meters of stone profiles within 8 hours. The processed profiles can achieve a glossiness of 90-120 degrees, with a smooth surface that requires no additional waxing, effortlessly achieving a reflective finish, ensuring excellent quality and visual appeal in the final product.

Parameter:

Serial | Name | Unit | Parameter |

1 | Number of shape wheel | Unit | 3 |

2 | Motor power of shape wheel | Kw | 7.5 |

3 | Diameter of shape wheel | mm | 180-200 |

4 | Number of polishing wheel | unit | 5 |

5 | Motor power of polishing wheel | Kw | 5.5 |

6 | Diameter of polishing wheel | mm | 150-220 |

7 | Max workable line width | mm | 250 |

8 | Workable width | mm | 30-400 |

9 | Workable thickness | mm | 10-70 |

10 | Workable speed | m/min | 0.3—3.0 |

11 | Total power | Kw | 58.63 |

12 | Power consumption | Kw | 50 |

13 | Water consumption(about) | L/min | 500 |

14 | External size | a×b×h | 10.30×2.00×1.80(m) |

15 | Weight(about) | T | 5 |