The YTQZ-A/2-1200 Two Blade CNC Tile Cutting Machine, independently developed by Foshan Yongtao Machinery, is a new type of CNC ceramic cutting equipment. This machine has successfully resolved the chipping issues commonly encountered in traditional cutting machines, earning its reputation as a top choice in tile processing production. It boasts unparalleled advantages over traditional cutting machines.

The YTQZ-A/2-1200 Two Blade CNC Tile Cutting Machine, independently developed by Foshan Yongtao Machinery, is a new type of CNC ceramic cutting equipment. This machine has successfully resolved the chipping issues commonly encountered in traditional cutting machines, earning its reputation as a top choice in tile processing production. It boasts unparalleled advantages over traditional cutting machines.

1、High-Precision CNC System: Utilizing a fully automated CNC system, it eliminates the cumbersome process of adjusting for multiple specifications. With a control precision within

0.01mm, it ensures cutting size accuracy.

2、Double-Blade Design: Equipped with both front and rear cutting heads, the front blade performs a partial depth pre-cut while the rear blade completes the cut, enabling automatic continuous cutting of tiles. The cutting process results in no chipping or size discrepancies, significantly enhancing cutting quality.

3、High Efficiency and Energy Saving: The machine is characterized by low breakage rates and stable performance, offering energy-saving, high-efficiency, and low processing costs. Its fast cutting speed and excellent results save substantial production costs for enterprises.

4、User-Friendly Operation System: The machine uses a touch-screen control system, making operation more convenient and intuitive. Users simply input the required size to quickly and accurately complete the cut, avoiding chipping and size deviation.

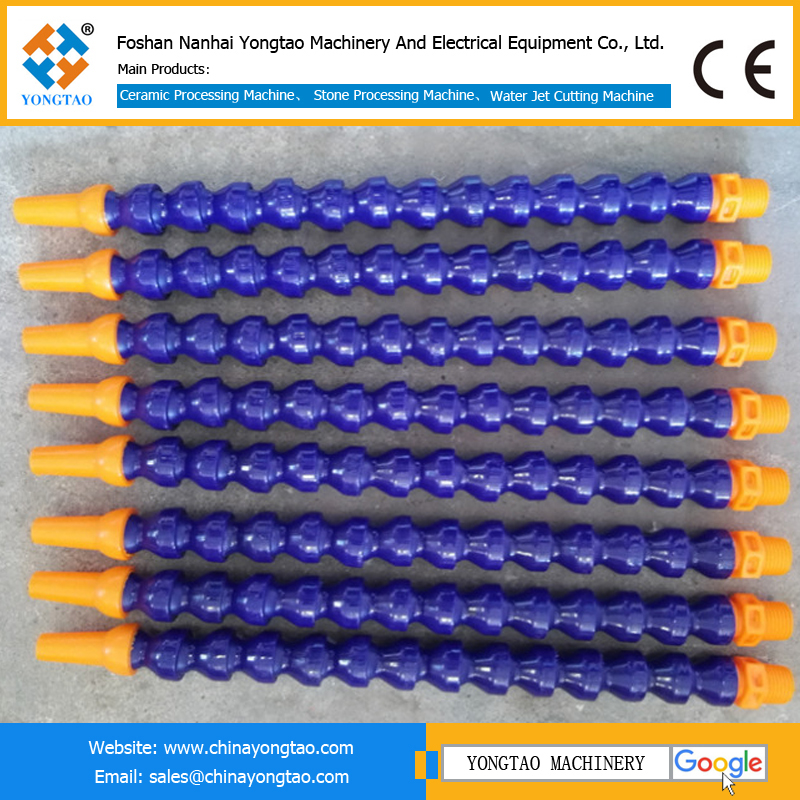

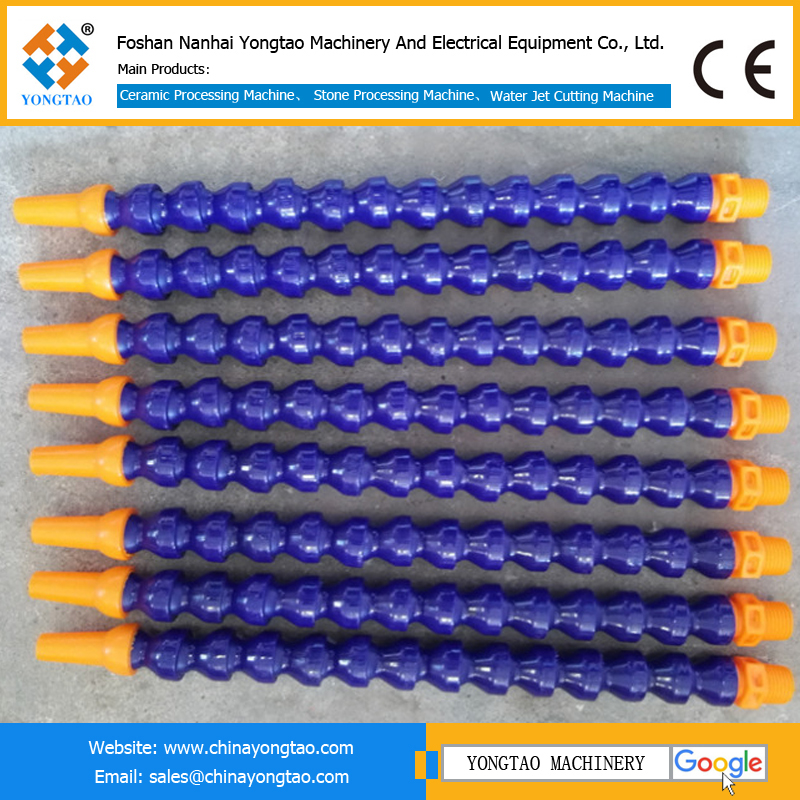

5、Precision Structural Design: The machine features a precision oil-immersed lead screw with synchronized in-and-out servo motor drive, and the cutting heads are equipped with both oil and water cooling systems. This effectively prevents high-temperature issues during high-speed operation, extending the machine's service life.

6、Ergonomic Design: The machine's exterior is equipped with a stainless steel water cover, preventing water splashes when the machine is in operation, and ensuring that the internal water flow exits with the belt. The beam adopts a grooved structure with the belt seated within, preventing belt elongation and displacement over time, thereby ensuring stable cutting dimensions.

7、Imported Components for Enhanced Performance: The machine uniquely uses imported precision lead screws and linear guides, combined with the Delta CNC system, to ensure smoother operation, higher precision, and more intuitive and convenient operation.

1、Elimination of Chipping Issues: With the front blade pre-cutting and the rear blade cutting through, the machine effectively resolves chipping problems, ensuring smooth and flat cutting edges.

2、High-Precision Cutting: The machine employs imported precision ball screws and linear guides, along with a high-precision servo system, keeping cutting errors within 0.1mm and ensuring processing accuracy.

3、Fully Automatic Control System: The Delta CNC system eliminates the tedious manual measurement adjustments. The backstop automatically adjusts to position with just a digital input on the control panel, achieving full automation.

4、Smooth Cutting Experience: The machine automatically adjusts speed during cutting, minimizing vibrations and ensuring a smooth and error-free cutting process, thereby improving overall production efficiency.

5、Cost Reduction and Efficiency Improvement: Compared to traditional manual cutting machines, this equipment can replace four manual tile cutting machines, requiring only two operators to achieve four times the workload, significantly reducing labor and machinery costs while also notably decreasing breakage rates.

6、User-Friendly Operation: The machine is easy to operate, allowing size adjustments in just 5 seconds, greatly enhancing work efficiency. This brings higher returns and customer satisfaction to tile processing plants and renovation companies.

The YTQZ-A/2-1200 Double-Blade CNC Ceramic Tile Cutting Machine, with its advanced design, superior performance, and energy-efficient features, stands as the optimal choice in tile processing production. This equipment not only increases production efficiency but also generates greater economic benefits for enterprises, making it an ideal tile cutting solution for ceramic processing plants and related industries.

Products Model and Technical Parameter:

YTQZ-A/2-1200 | Units | Numbers |

Processing Size | MM | 1200*1200 |

Cutting head | PCS | 2 |

Motor power of Axis | KW | 4 |

Total Capacity | KW | 9.1 |

Machine Weight | KG | 1200 |

Machine Size | MM | 2400*2000*1800 |

The YTQZ-A/2-1200 Two Blade CNC Tile Cutting Machine, independently developed by Foshan Yongtao Machinery, is a new type of CNC ceramic cutting equipment. This machine has successfully resolved the chipping issues commonly encountered in traditional cutting machines, earning its reputation as a top choice in tile processing production. It boasts unparalleled advantages over traditional cutting machines.

1、High-Precision CNC System: Utilizing a fully automated CNC system, it eliminates the cumbersome process of adjusting for multiple specifications. With a control precision within

0.01mm, it ensures cutting size accuracy.

2、Double-Blade Design: Equipped with both front and rear cutting heads, the front blade performs a partial depth pre-cut while the rear blade completes the cut, enabling automatic continuous cutting of tiles. The cutting process results in no chipping or size discrepancies, significantly enhancing cutting quality.

3、High Efficiency and Energy Saving: The machine is characterized by low breakage rates and stable performance, offering energy-saving, high-efficiency, and low processing costs. Its fast cutting speed and excellent results save substantial production costs for enterprises.

4、User-Friendly Operation System: The machine uses a touch-screen control system, making operation more convenient and intuitive. Users simply input the required size to quickly and accurately complete the cut, avoiding chipping and size deviation.

5、Precision Structural Design: The machine features a precision oil-immersed lead screw with synchronized in-and-out servo motor drive, and the cutting heads are equipped with both oil and water cooling systems. This effectively prevents high-temperature issues during high-speed operation, extending the machine's service life.

6、Ergonomic Design: The machine's exterior is equipped with a stainless steel water cover, preventing water splashes when the machine is in operation, and ensuring that the internal water flow exits with the belt. The beam adopts a grooved structure with the belt seated within, preventing belt elongation and displacement over time, thereby ensuring stable cutting dimensions.

7、Imported Components for Enhanced Performance: The machine uniquely uses imported precision lead screws and linear guides, combined with the Delta CNC system, to ensure smoother operation, higher precision, and more intuitive and convenient operation.

1、Elimination of Chipping Issues: With the front blade pre-cutting and the rear blade cutting through, the machine effectively resolves chipping problems, ensuring smooth and flat cutting edges.

2、High-Precision Cutting: The machine employs imported precision ball screws and linear guides, along with a high-precision servo system, keeping cutting errors within 0.1mm and ensuring processing accuracy.

3、Fully Automatic Control System: The Delta CNC system eliminates the tedious manual measurement adjustments. The backstop automatically adjusts to position with just a digital input on the control panel, achieving full automation.

4、Smooth Cutting Experience: The machine automatically adjusts speed during cutting, minimizing vibrations and ensuring a smooth and error-free cutting process, thereby improving overall production efficiency.

5、Cost Reduction and Efficiency Improvement: Compared to traditional manual cutting machines, this equipment can replace four manual tile cutting machines, requiring only two operators to achieve four times the workload, significantly reducing labor and machinery costs while also notably decreasing breakage rates.

6、User-Friendly Operation: The machine is easy to operate, allowing size adjustments in just 5 seconds, greatly enhancing work efficiency. This brings higher returns and customer satisfaction to tile processing plants and renovation companies.

The YTQZ-A/2-1200 Double-Blade CNC Ceramic Tile Cutting Machine, with its advanced design, superior performance, and energy-efficient features, stands as the optimal choice in tile processing production. This equipment not only increases production efficiency but also generates greater economic benefits for enterprises, making it an ideal tile cutting solution for ceramic processing plants and related industries.

Products Model and Technical Parameter:

YTQZ-A/2-1200 | Units | Numbers |

Processing Size | MM | 1200*1200 |

Cutting head | PCS | 2 |

Motor power of Axis | KW | 4 |

Total Capacity | KW | 9.1 |

Machine Weight | KG | 1200 |

Machine Size | MM | 2400*2000*1800 |