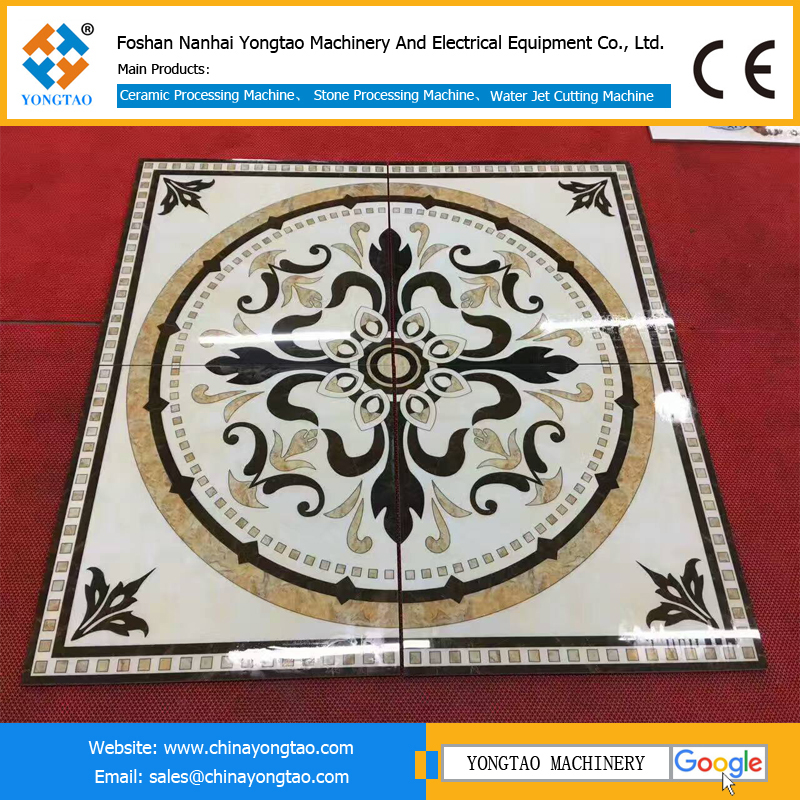

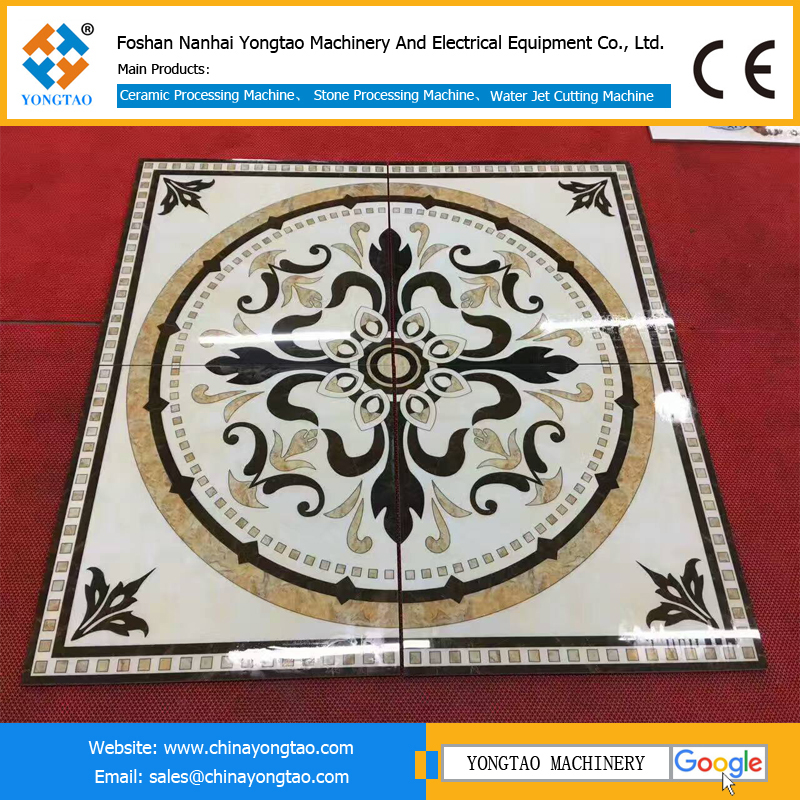

Yongtao AB 5-axis water jet is a cnc water jet cutting machine for professional stone cutting. The maximum cutting size is 3m X 2m. It is mainly used for cutting marble floor medallions, and can also cut other materials. For example: cutting tiles, sintered stone, glass, metal and other materials

(1) all steel of working talk made from GB steel,outsize seal design adopt stainless steel,beautiful and practical,durable in use.

(2) screw are adopt oil-immersed,waterproof and dustproof,assure the life of working table,using import brand servo motor.

(4) Screw:TAIWAN TBI

(5) Guide rail:TAIWAN TBI

(6) Motor type of longitudinal beam and cross beam:(TAIWAN)sevor motor

(7) Dustproof mode:stainless steel dustproof cover

(8) Material of working table appearance:stainless steel

(9) All electric cable:import

Yongtao AB 5-axis water jet is a cnc water jet cutting machine for professional stone cutting. The maximum cutting size is 3m X 2m. It is mainly used for cutting marble floor medallions, and can also cut other materials. For example: cutting tiles, sintered stone, glass, metal and other materials

The 5-axis water jet cutting machine is an advanced water cutting device that uses high-pressure water flow combined with abrasives to cut various materials. Its five axes are X-axis, Y-axis, Z-axis, A-axis, and B or C-axis. The functions of these 5 axes are as follows:

X-axis:Controls the left and right movement of the cutting head in the horizontal direction. The X-axis is usually parallel to the length of the cutting table and is key to achieving the horizontal cutting path.

Y-axis:Controls the forward and backward movement of the cutting head in a direction perpendicular to the X-axis, usually parallel to the width of the cutting table. It works in conjunction with the X-axis to achieve arbitrary cutting paths on a two-dimensional plane.

Z-axis:Controls the up and down movement of the cutting head in the vertical direction, adjusting the distance between the cutting head and the material surface to accommodate different material thicknesses.

A-axis:Controls the rotation of the cutting head, usually around the X-axis, to adjust the tilt angle of the cutting head, enabling bevel cutting.

B-axis or C-axis:Controls another rotational angle of the cutting head. The B-axis rotates around the Y-axis, while the C-axis rotates around the Z-axis. This axis is used to adjust the direction of the cutting head in more complex three-dimensional cutting.

In the AB five-axis system, the A-axis rotates around the X-axis, and the B-axis rotates around the Y-axis. This configuration allows the cutting head to adjust angles within a range of ±5-10°, making it particularly suitable for smaller angle cuts. The combination of the A-axis and B-axis can achieve a wide range of cutting angles, making the AB five-axis system more suitable for cutting stone, tile floor medallions, and similar applications.

In the AC five-axis system, the A-axis still rotates around the X-axis, while the C-axis rotates around the Z-axis. The advantage of this configuration is that the C-axis can more flexibly adjust the direction of the cutting head, especially when 360-degree rotational cutting is required. The AC five-axis system is commonly used for 45-degree cuts on sintered stone, such as inner 45-degree and outer 45-degree cuts, enabling more precise completion of various 45° bevel cutting tasks.

AB 5 Axis Water Jet Machinery:

Parameter:

Serial | YJ-1313 | YJ-2015 | YJ-2515 | YJ-3020 | YJ-4020 | |||

Structure type | Cantilever type | Cantilever/bridge type | Bridge type | Bridge type | Bridge type | |||

Working table size | 1400*1400 | 2100*1600 | 2600*1600 | 3100*2100 | 4100*2100 | |||

Cutting stroke | X | 1200mm | 1500mm | 1500mm | 3000mm | 4000mm | ||

Y | 1200mm | 2000mm | 2500mm | 2000mm | 2000mm | |||

Z | 150mm | 150mm | 150mm | 150mm | 150mm | |||

CNC control system | Alternating current sevor | |||||||

Accuracy | Cutting accuracy | ±0.01mm | ||||||

Repeat accuracy | ±0.005mm | |||||||

Fast location speed | 6000mm/min | |||||||

Power supply | 200V/380v/415 50/60Hz | |||||||

item | parameter |

Application material | Almost all material |

Max cutting size | 2000*3000 |

Cutting accuracy | ±0.1mm |

Repeat accuracy | 0.025mm |

Fast location accuracy | 1-15m/min |

Max no-load speed | 8000mm/min |

Max working speed | Polish tile:600*600 tile 1.8-2.0m/min 800*800 tile1.5-1.8m/min |

Max pressure | 420MPa |

Workable pressure | 350-380MPa |

0.4-0.8MPa | |

Max water displacement | 3.7L/min |

Max sand displacement | 190g/min |

Max number of stroke | 60次/min |

Z axis stroke | 130mm |

Control system | Windows XP |

Diameter of sand pipe nozzle | 1.0mm |

Diameter of gem nozzle | 0.33mm |

Drawing software | Auto CAD |

(1) all steel of working talk made from GB steel,outsize seal design adopt stainless steel,beautiful and practical,durable in use.

(2) screw are adopt oil-immersed,waterproof and dustproof,assure the life of working table,using import brand servo motor.

(4) Screw:TAIWAN TBI

(5) Guide rail:TAIWAN TBI

(6) Motor type of longitudinal beam and cross beam:(TAIWAN)sevor motor

(7) Dustproof mode:stainless steel dustproof cover

(8) Material of working table appearance:stainless steel

(9) All electric cable:import

Yongtao AB 5-axis water jet is a cnc water jet cutting machine for professional stone cutting. The maximum cutting size is 3m X 2m. It is mainly used for cutting marble floor medallions, and can also cut other materials. For example: cutting tiles, sintered stone, glass, metal and other materials

The 5-axis water jet cutting machine is an advanced water cutting device that uses high-pressure water flow combined with abrasives to cut various materials. Its five axes are X-axis, Y-axis, Z-axis, A-axis, and B or C-axis. The functions of these 5 axes are as follows:

X-axis:Controls the left and right movement of the cutting head in the horizontal direction. The X-axis is usually parallel to the length of the cutting table and is key to achieving the horizontal cutting path.

Y-axis:Controls the forward and backward movement of the cutting head in a direction perpendicular to the X-axis, usually parallel to the width of the cutting table. It works in conjunction with the X-axis to achieve arbitrary cutting paths on a two-dimensional plane.

Z-axis:Controls the up and down movement of the cutting head in the vertical direction, adjusting the distance between the cutting head and the material surface to accommodate different material thicknesses.

A-axis:Controls the rotation of the cutting head, usually around the X-axis, to adjust the tilt angle of the cutting head, enabling bevel cutting.

B-axis or C-axis:Controls another rotational angle of the cutting head. The B-axis rotates around the Y-axis, while the C-axis rotates around the Z-axis. This axis is used to adjust the direction of the cutting head in more complex three-dimensional cutting.

In the AB five-axis system, the A-axis rotates around the X-axis, and the B-axis rotates around the Y-axis. This configuration allows the cutting head to adjust angles within a range of ±5-10°, making it particularly suitable for smaller angle cuts. The combination of the A-axis and B-axis can achieve a wide range of cutting angles, making the AB five-axis system more suitable for cutting stone, tile floor medallions, and similar applications.

In the AC five-axis system, the A-axis still rotates around the X-axis, while the C-axis rotates around the Z-axis. The advantage of this configuration is that the C-axis can more flexibly adjust the direction of the cutting head, especially when 360-degree rotational cutting is required. The AC five-axis system is commonly used for 45-degree cuts on sintered stone, such as inner 45-degree and outer 45-degree cuts, enabling more precise completion of various 45° bevel cutting tasks.

AB 5 Axis Water Jet Machinery:

Parameter:

Serial | YJ-1313 | YJ-2015 | YJ-2515 | YJ-3020 | YJ-4020 | |||

Structure type | Cantilever type | Cantilever/bridge type | Bridge type | Bridge type | Bridge type | |||

Working table size | 1400*1400 | 2100*1600 | 2600*1600 | 3100*2100 | 4100*2100 | |||

Cutting stroke | X | 1200mm | 1500mm | 1500mm | 3000mm | 4000mm | ||

Y | 1200mm | 2000mm | 2500mm | 2000mm | 2000mm | |||

Z | 150mm | 150mm | 150mm | 150mm | 150mm | |||

CNC control system | Alternating current sevor | |||||||

Accuracy | Cutting accuracy | ±0.01mm | ||||||

Repeat accuracy | ±0.005mm | |||||||

Fast location speed | 6000mm/min | |||||||

Power supply | 200V/380v/415 50/60Hz | |||||||

item | parameter |

Application material | Almost all material |

Max cutting size | 2000*3000 |

Cutting accuracy | ±0.1mm |

Repeat accuracy | 0.025mm |

Fast location accuracy | 1-15m/min |

Max no-load speed | 8000mm/min |

Max working speed | Polish tile:600*600 tile 1.8-2.0m/min 800*800 tile1.5-1.8m/min |

Max pressure | 420MPa |

Workable pressure | 350-380MPa |

0.4-0.8MPa | |

Max water displacement | 3.7L/min |

Max sand displacement | 190g/min |

Max number of stroke | 60次/min |

Z axis stroke | 130mm |

Control system | Windows XP |

Diameter of sand pipe nozzle | 1.0mm |

Diameter of gem nozzle | 0.33mm |

Drawing software | Auto CAD |