Yongtao is a well-known supplier of 3-axis water jet glass cutting machines in China, providing customers with high-pressure water jet cutting machines of various specifications to meet the needs of customers for cutting various materials. For example: cutting glass, stone, tiles, metal, etc. Cutting tabletop holes, with a wide range of applications.

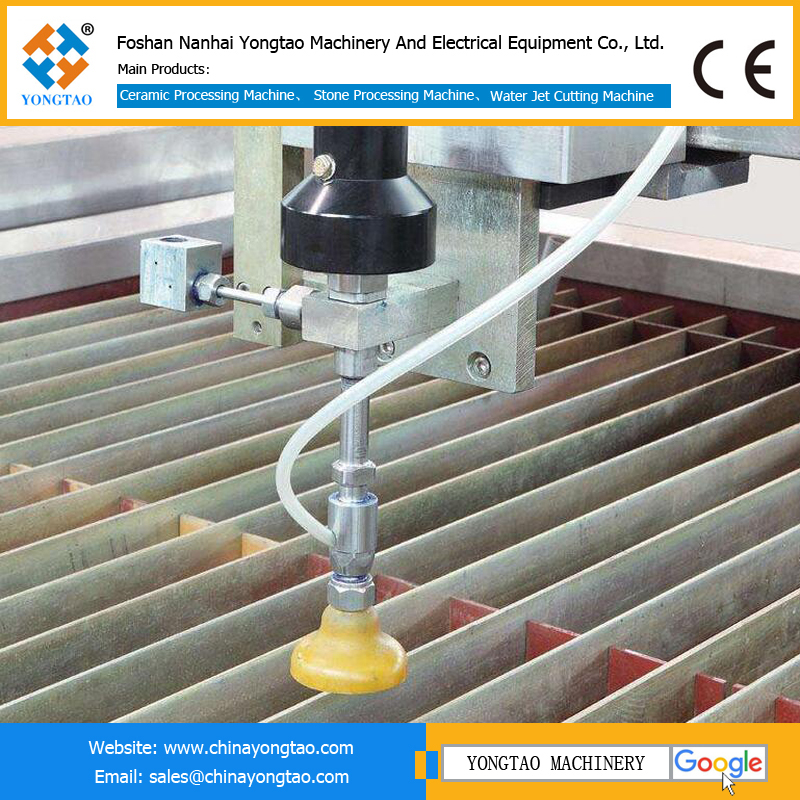

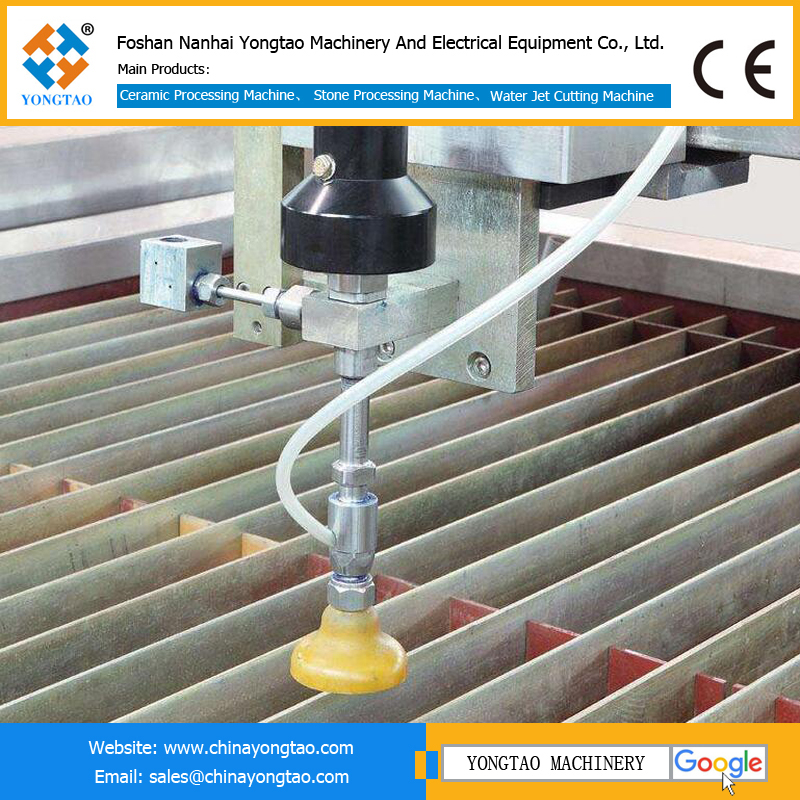

(1) all steel of working talk made from GB steel,outsize seal design adopt stainless steel,beautiful and practical,durable in use.

(2) screw are adopt oil-immersed,waterproof and dustproof,assure the life of working table,using import brand servo motor.

Screw:TAIWAN TBI

Guide rail:TAIWAN TBI

Motor type of longitudinal beam and cross beam:(TAIWAN)sevor motor

Dustproof mode:stainless steel dustproof cover

Material of working table appearance:stainless steel

All electric cable:import

Yongtao is a well-known supplier of 3-axis water jet glass cutting machines in China, providing customers with high-pressure water jet cutting machines of various specifications to meet the needs of customers for cutting various materials. For example: cutting glass, stone, tiles, metal, etc. Cutting tabletop holes, with a wide range of applications.

A water jet cutting machine is a device that cuts materials using high-pressure water jets. It is widely used in processing glass, stone, ceramics, metals, and various other materials. By utilizing ultra-high-pressure water through a small nozzle, the machine directs the water at the material surface at an extremely high speed, achieving precise cutting. The water jet cutting process does not generate heat, which minimizes the impact on the material's structure and properties, making it particularly suitable for processing heat-sensitive materials.

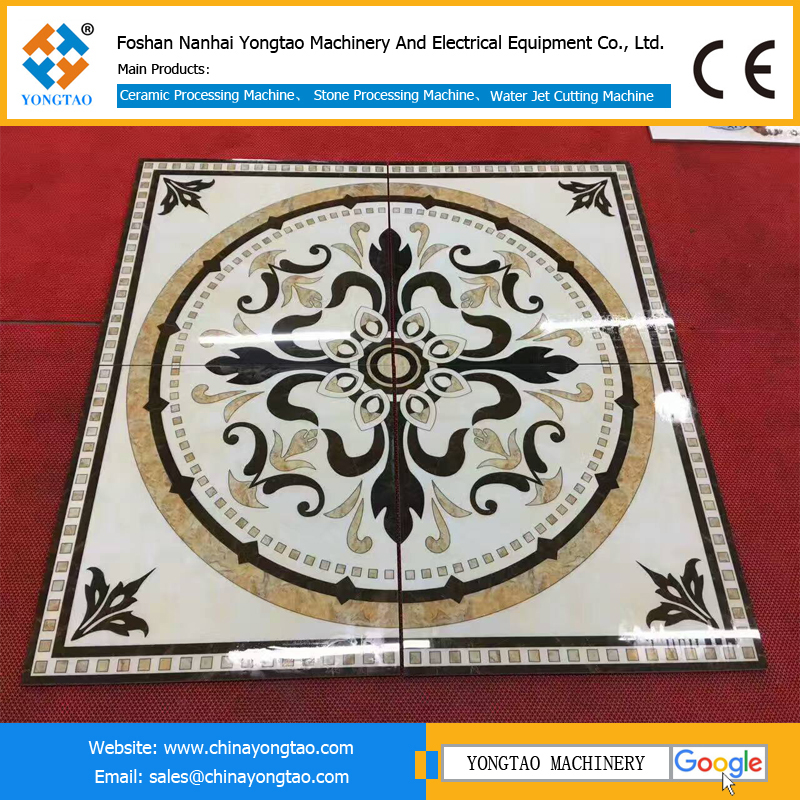

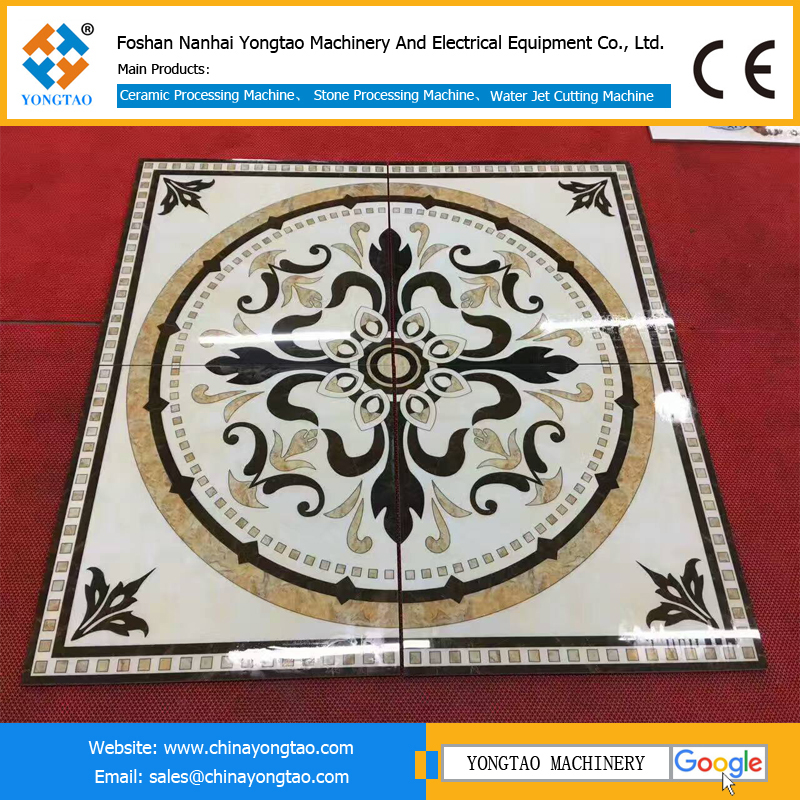

The 3-axis water jet glass cutting machine has broad applications in the glass processing industry. It can cut various thicknesses of glass, including standard glass, tempered glass, and laminated glass. The machine's three-axis system allows movement in the X, Y, and Z directions, making the cutting process more flexible and capable of producing complex shapes and patterns. Due to the non-contact nature of water jet cutting, the machine maintains the integrity of the glass, preventing chipping or cracking, and ensuring high-quality finished products.

1、The 3-axis water jet machine can precisely control the water jet's path and pressure, achieving high-precision cuts that meet the demands of high-quality glass products.

2、In addition to cutting glass, the machine can also process materials like stone and ceramics, making it suitable for various fields such as architectural decoration and industrial manufacturing.

3、As it employs cold cutting technology, water jet cutting does not affect the material with heat, preventing deformation or damage due to thermal stress.

4、The water jet cutting process does not produce harmful gases or dust, aligning with modern industrial environmental standards.

5、The 3-axis water jet cutting machine is highly automated and easy to operate, making it ideal for mass production, as well as custom processing of complex designs.

Overall, the 3-axis water jet glass cutter has become an essential piece of equipment in the glass processing industry due to its high precision, versatility, and environmental benefits. Whether in architectural decoration, home manufacturing, or industrial applications, this machine provides excellent cutting results, ensuring the quality of finished products.

Parameter:

Serial | YJ-1313 | YJ-2015 | YJ-2515 | YJ-3020 | YJ-4020 | |||

Structure type | Cantilever type | Cantilever/bridge type | Bridge type | Bridge type | Bridge type | |||

Working table size | 1400*1400 | 2100*1600 | 2600*1600 | 3100*2100 | 4100*2100 | |||

Cutting stroke | X | 1200mm | 1500mm | 1500mm | 3000mm | 4000mm | ||

Y | 1200mm | 2000mm | 2500mm | 2000mm | 2000mm | |||

Z | 150mm | 150mm | 150mm | 150mm | 150mm | |||

CNC control system | Alternating current sevor | |||||||

Accuracy | Cutting accuracy | ±0.01mm | ||||||

Repeat accuracy | ±0.005mm | |||||||

Fast location speed | 6000mm/min | |||||||

Power supply | 200V/380v/415 50/60Hz | |||||||

item | parameter |

Application material | Almost all material |

Max cutting size | 2000*1500 |

Cutting accuracy | ±0.1mm |

Repeat accuracy | 0.025mm |

Fast location accuracy | 1-15m/min |

Max no-load speed | 8000mm/min |

Max working speed | Polish tile:600*600 tile 1.8-2.0m/min 800*800 tile1.5-1.8m/min |

Max pressure | 420MPa |

Workable pressure | 350-380MPa |

0.4-0.8MPa | |

Max water displacement | 3.7L/min |

Max sand displacement | 190g/min |

Max number of stroke | 60次/min |

Z axis stroke | 130mm |

Control system | Windows XP |

Diameter of sand pipe nozzle | 1.0mm |

Diameter of gem nozzle | 0.33mm |

Drawing software | Auto CAD |

(1) all steel of working talk made from GB steel,outsize seal design adopt stainless steel,beautiful and practical,durable in use.

(2) screw are adopt oil-immersed,waterproof and dustproof,assure the life of working table,using import brand servo motor.

Screw:TAIWAN TBI

Guide rail:TAIWAN TBI

Motor type of longitudinal beam and cross beam:(TAIWAN)sevor motor

Dustproof mode:stainless steel dustproof cover

Material of working table appearance:stainless steel

All electric cable:import

Yongtao is a well-known supplier of 3-axis water jet glass cutting machines in China, providing customers with high-pressure water jet cutting machines of various specifications to meet the needs of customers for cutting various materials. For example: cutting glass, stone, tiles, metal, etc. Cutting tabletop holes, with a wide range of applications.

A water jet cutting machine is a device that cuts materials using high-pressure water jets. It is widely used in processing glass, stone, ceramics, metals, and various other materials. By utilizing ultra-high-pressure water through a small nozzle, the machine directs the water at the material surface at an extremely high speed, achieving precise cutting. The water jet cutting process does not generate heat, which minimizes the impact on the material's structure and properties, making it particularly suitable for processing heat-sensitive materials.

The 3-axis water jet glass cutting machine has broad applications in the glass processing industry. It can cut various thicknesses of glass, including standard glass, tempered glass, and laminated glass. The machine's three-axis system allows movement in the X, Y, and Z directions, making the cutting process more flexible and capable of producing complex shapes and patterns. Due to the non-contact nature of water jet cutting, the machine maintains the integrity of the glass, preventing chipping or cracking, and ensuring high-quality finished products.

1、The 3-axis water jet machine can precisely control the water jet's path and pressure, achieving high-precision cuts that meet the demands of high-quality glass products.

2、In addition to cutting glass, the machine can also process materials like stone and ceramics, making it suitable for various fields such as architectural decoration and industrial manufacturing.

3、As it employs cold cutting technology, water jet cutting does not affect the material with heat, preventing deformation or damage due to thermal stress.

4、The water jet cutting process does not produce harmful gases or dust, aligning with modern industrial environmental standards.

5、The 3-axis water jet cutting machine is highly automated and easy to operate, making it ideal for mass production, as well as custom processing of complex designs.

Overall, the 3-axis water jet glass cutter has become an essential piece of equipment in the glass processing industry due to its high precision, versatility, and environmental benefits. Whether in architectural decoration, home manufacturing, or industrial applications, this machine provides excellent cutting results, ensuring the quality of finished products.

Parameter:

Serial | YJ-1313 | YJ-2015 | YJ-2515 | YJ-3020 | YJ-4020 | |||

Structure type | Cantilever type | Cantilever/bridge type | Bridge type | Bridge type | Bridge type | |||

Working table size | 1400*1400 | 2100*1600 | 2600*1600 | 3100*2100 | 4100*2100 | |||

Cutting stroke | X | 1200mm | 1500mm | 1500mm | 3000mm | 4000mm | ||

Y | 1200mm | 2000mm | 2500mm | 2000mm | 2000mm | |||

Z | 150mm | 150mm | 150mm | 150mm | 150mm | |||

CNC control system | Alternating current sevor | |||||||

Accuracy | Cutting accuracy | ±0.01mm | ||||||

Repeat accuracy | ±0.005mm | |||||||

Fast location speed | 6000mm/min | |||||||

Power supply | 200V/380v/415 50/60Hz | |||||||

item | parameter |

Application material | Almost all material |

Max cutting size | 2000*1500 |

Cutting accuracy | ±0.1mm |

Repeat accuracy | 0.025mm |

Fast location accuracy | 1-15m/min |

Max no-load speed | 8000mm/min |

Max working speed | Polish tile:600*600 tile 1.8-2.0m/min 800*800 tile1.5-1.8m/min |

Max pressure | 420MPa |

Workable pressure | 350-380MPa |

0.4-0.8MPa | |

Max water displacement | 3.7L/min |

Max sand displacement | 190g/min |

Max number of stroke | 60次/min |

Z axis stroke | 130mm |

Control system | Windows XP |

Diameter of sand pipe nozzle | 1.0mm |

Diameter of gem nozzle | 0.33mm |

Drawing software | Auto CAD |